The reverse osmosis membrane is the most important part of a reverse osmosis water treatment plant because it affects both the water quality and the system's efficiency. Proper upkeep makes sure that these advanced filter systems keep providing clean water that meets high standards for industry while avoiding major changes to how they operate. For manufacturing plants, drug companies, and city-run water treatment plants, regularly cleaning membrane parts, keeping an eye on them, and fixing problems before they happen makes the equipment last longer and lowers the overall cost of ownership.

Understanding Reverse Osmosis Membranes and Their Role in Water Purification

When pressure is used, reverse osmosis membranes act as fussy walls that keep solids, pollutants, and other things out of water. These membranes are semipermeable and have pores smaller than 0.0001 microns. They can keep out more than 99% of most salts, germs, and organic molecules.

Types of RO Membranes and Their Applications

These days, water treatment plants mostly use two membrane technologies. Thin Film Composite (TFC) membranes are better at rejecting salt and lasting a long time, which makes them perfect for commercial uses that need to keep water quality stable. These membranes hold up better than other materials when they come into contact with chlorine, and they keep working well even when conditions change. Cellulose triacetate (CTA) membranes are a cheap way to do certain things where low rejection rates are acceptable, but they need to be handled carefully so that biological breakdown doesn't happen.

Membrane Performance Characteristics

TFC membranes with high rejection rates provide great filter efficiency and keep energy use between 3 and 6 kWh/m³. As long as recovery rates are 75%, these systems can produce a lot of water without creating much trash, which makes them affordable for use in large-scale activities. The flexible design lets you change the capacity from 1,000 to 100,000 gallons per day, which works for a range of industries, from small factories to large citywide treatment plants.

Key Challenges in Maintaining RO Membranes for Optimal Performance

The main threat to system efficiency is membrane fouling. It shows up in different ways that lower water output and raise energy use. Understanding these issues makes it possible to use preventative care methods, keep the health of the membrane, and lengthen the service life.

Common Fouling Mechanisms

Biological fouling happens when bacteria build up on the sides of the reverse osmosis membrane and form biofilms that make it harder for water to move and lower rejection rates. Scaling happens when minerals that are dissolved in water settle on membranes. This is a big problem in situations where high-hardness feedwater is used. When natural organic matter builds up, it is called organic fouling. On the other hand, colloidal fouling happens when bits that are floating in the fluid go through preparation systems.

Early Warning Signs and Monitoring

Operational signs show the state of the membrane before a total breakdown. Getting worse permeate flow rates and higher difference pressure across membrane banks and salt passage levels mean that problems are starting to form and need to be fixed right away. Advanced tracking systems keep an eye on these factors all the time. This makes it possible to plan maintenance ahead of time, which stops unexpected downtime and expensive emergency repairs.

Best Practices for Enhancing RO Membrane Lifespan and System Efficiency

Using thorough maintenance procedures makes sure that the membrane performance stays the same and that running costs are lowered. These methods use both scheduled preventive cleaning and tracking in real-time to keep the membrane working at its best for the entire lifetime of the product.

Cleaning Protocols and Chemical Selection

Effective cleaning starts with figuring out what kind of dirt is on the membrane. This can be done by either a membrane autopsy or performance data analysis. Here are the most important cleaning methods that help restore membranes:

- Alkaline cleaning: High-pH solutions that don't hurt membrane materials but break down proteins and remove organic deposits are used to get rid of biofilms and organic fouling.

- Acid cleaning: This gets rid of mineral scaling by carefully exposing the surface to acid, which removes layers of calcium carbonate, silica, and metal oxides without damaging the membrane.

- Biocide treatment: uses approved disinfectants that break through biofilms and get rid of microbial contamination to control biological growth.

- Enzyme cleaning: Biological catalysts are used to break down complex materials that are hard to clean at low temperatures.

When these cleaning methods are used in the right order, they work together to make the membrane work like it did when it was new and greatly extend its useful life.

Operating Parameter Optimization

Keeping the best working conditions slows down aging and lowers stress on the reverse osmosis membrane. Keeping the temperature between 15 and 25 °C reduces heat stress and makes sure that the flow rates are high enough. Pressure control stops the membrane from getting compacted while still keeping enough moving force for contaminant rejection. Finding the best flow rate makes sure that all membrane surfaces get the same amount of water. This stops fouling in certain areas and concentration polarization.

Comparing Reverse Osmosis Membranes and Selecting the Right Solution

Choosing a membrane has a big effect on the long-term performance of a system and the cost of running it. Comparing technologies with specific application needs makes sure that water quality goals are met and that the best returns on investments are gotten.

Membrane Technology Comparison

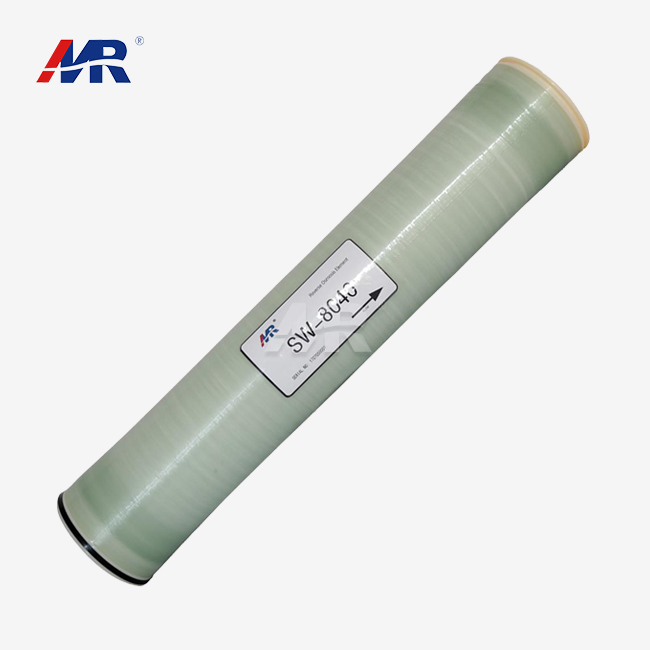

Top membrane makers provide a range of technologies that are useful for a variety of situations involving a reverse osmosis membrane. In city uses, low-pressure membranes use less energy, and in pharmaceutical and semiconductor manufacturing, high-rejection membranes make sure ultrapure water is made. Seawater membranes are able to handle high-salt conditions in desalination plants, and brackish water membranes are used to get the best performance out of freshwater uses.

Supplier Evaluation Criteria

Choosing trustworthy membrane providers means looking at how much expert help they offer, how quickly they can deliver replacement parts, and how fast they respond to service requests. Well-known companies offer long warranties, efficiency promises, and expert help for the lifetime of the membrane. Local distribution networks make sure that parts are delivered quickly and service is available on-site. This keeps repairs from disrupting operations.

Company Introduction and Product Service Information

Companies, cities, and industries around the world can get all of their water cleaning needs met by Guangdong Morui Environmental Technology Co., Ltd. We've been doing this for over 14 years, and 20 trained engineers can help explain the tricky issues with modern water purification to the more than 500 workers who work here.

Advanced RO System Capabilities

Our reverse osmosis systems use the newest reverse osmosis membrane technology and have tracking features that make sure they always work in tough situations. The modular design makes it easy to add more room when production needs grow, and the small footprints mean that less space is needed overall. You can change the settings to deal with different water quality problems, from feedwater with a lot of salt to complicated process lines in the factory.

Comprehensive Service Portfolio

We help with every part of a project, from designing and installing equipment to ensuring it works and providing ongoing expert support. Our membrane production plant ensures that the necessary parts are always in stock. Also, working with top makers like Shimge Water Pumps and Runxin Valves makes sure that the system stays reliable. Installation and testing services in one place cut down on project time frames and make sure that the system works perfectly from the very beginning.

Conclusion

Membranes, operational efficiency, and careful tracking are all parts of reverse osmosis plant maintenance that need to be done in a planned way. Understanding membrane technology, using good cleaning methods, and choosing the right tools will keep things working well over time and lower the cost of running things. Using advanced membrane materials, making sure that the system is properly maintained, and having solid technical help on hand all the time are all ways to create long-lasting solutions for treating water that meet the needs of the changing industry. Buying good membranes and skilled repair services protects your equipment and helps it run better for the whole time it is in use.

FAQ

Q1: How often do you need to clean reverse osmosis membranes?

A: How often you clean depends on the quality of the feedwater and how the machine is working. In general, membranes need to be cleaned when the difference pressure goes up by 10% to 15% over the baseline level or when the permeate flow goes down by 10%. Most industrial systems need to be cleaned every three to six months, but systems that get very dirty may need to be cleaned every month.

Q2: What are the signs that a membrane needs to be replaced?

A: When cleaning doesn't get the membrane working well enough again, it has to be replaced. Key signs are the steadily falling quality of the permeate, not being able to reach the goal flow rates after cleaning, and physical damage to the membrane elements. When salt intake is higher than it should be, even after cleaning, replacing it makes sure that the system keeps working well.

Q3: Can you mix different kinds of membranes in the same RO system?

A: It is not a good idea to mix different membrane types in the same pressure tank because it makes things harder to operate and causes uneven performance. But in different steps of multi-stage systems, which are set up so that each stage has its own purpose or set of rules for how it should work, different kinds of membranes can be used.

Partner with Morui for Superior RO Solutions

Ready to optimize your water treatment operations with advanced membrane technology? Morui delivers comprehensive reverse osmosis solutions backed by decades of engineering expertise and proven performance across diverse industrial applications. Our team provides personalized consultation to identify the ideal membrane configuration for your specific requirements, whether you need a reliable reverse osmosis membrane supplier for ongoing operations or complete system upgrades. Contact us at benson@guangdongmorui.com to discuss your project requirements and discover how our advanced membrane technology can enhance your water treatment efficiency while reducing operational costs.

References

1. American Water Works Association. "Reverse Osmosis and Nanofiltration: Manual of Water Supply Practices M46." Second Edition, Denver: AWWA, 2018.

2. Greenlee, Lauren F., et al. "Reverse osmosis desalination: Water sources, technology, and today's challenges." Water Research, vol. 43, no. 9, 2009, pp. 2317-2348.

3. Membrane Technology and Research Inc. "Industrial Water Treatment Handbook: Membrane Processes." Water Treatment Solutions, Third Edition, 2019.

4. International Desalination Association. "Membrane System Design and Operation Guidelines for Reverse Osmosis Plants." IDA Technical Guidelines, 2020.

5. Baker, Richard W. "Membrane Technology and Applications: Industrial Water Treatment." Third Edition, John Wiley & Sons, 2020.

6. World Health Organization. "Guidelines for Drinking-water Quality: Membrane Technologies in Water Treatment." Fourth Edition, Geneva: WHO Press, 2017.

_1745823981883.webp)