DTRO Membrane vs Traditional RO Membrane: Efficiency and Performance Comparison

Industrial sites have to make a big choice between DTRO membranes and standard reverse osmosis systems. This choice affects both the speed of operations and the costs over time. DTRO membrane technology works better at cleaning high-concentration wastewater streams. It works especially well with heavy metal effluents, landfill leachate, and complex industrial wastewater, where traditional spiral-wound membranes have trouble with fouling and low recovery rates.

Introduction

The way that industrial water is handled has changed because of membrane technologies. They have good methods that last a long time that can be used to make drugs, electronics, food, and public services. People who buy from other businesses need to choose the right membrane technology because it often affects how well medicines work, how well processes run, and how much money is saved.

More and more people want to know the difference between disc-tube reverse osmosis and other membrane systems as rules about the environment get stricter and the cost of cleaning water goes up. For decades, standard RO membranes have worked well in the industry. However, new problems with cleaning complex wastewater streams have shown that we need stronger options.

This in-depth study looks at the main ways that DTRO and regular RO membranes are different, focusing on how they work, how much they cost, and how useful they are. The comparison is meant to help people who work in buying make smart decisions that meet the needs of their unique industrial water treatment needs. This will help them get the most out of their membrane technology purchases over time and make the most of the projects they work on.

Understanding DTRO and Traditional RO Membrane Technologies

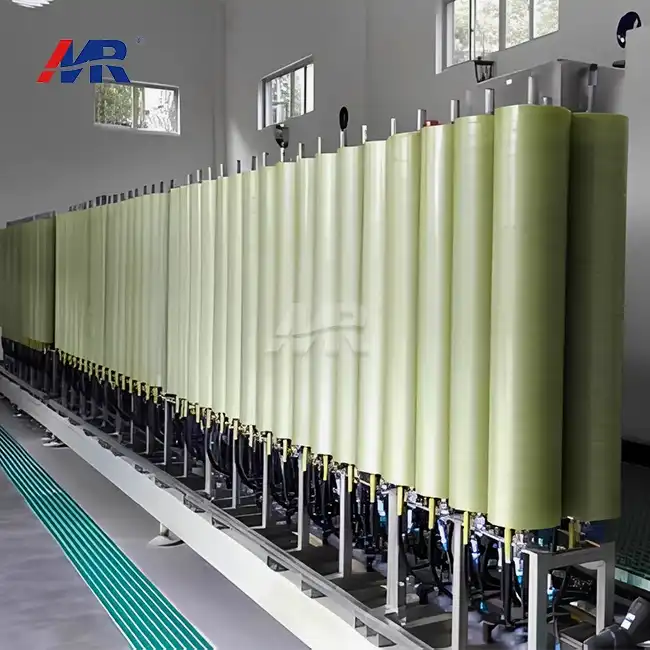

In terms of how it is built, disc-tube reverse osmosis is very different from the spiral-wound versions that have been predominant in the market for decades. DTRO membranes have unique disc tube arrangements that create turbulent flow patterns. This keeps contaminants from building up on the membrane surfaces while keeping the filter performance constant.

Disc-Tube Design Innovation

DTRO technology uses flat sheet membranes grouped in a disc shape around a center pierced tube to make open flow lines that don't get clogged or foul. This design makes it possible to treat high-turbidity feedwater with more than 50,000 mg/L of total dissolved solids effectively, which makes it perfect for tough industrial uses.

When the discs are arranged in a spiral, they form flow patterns that clean naturally. This means that chemical cleaning processes are needed less often than with traditional spiral-wound membranes. Each membrane disc works on its own, so repair can be done in specific areas without having to shut down whole membrane trains.

Traditional RO Membrane Limitations

Conventional spiral-wound membranes work on well-known pressure-driven filtration principles, but they have big problems when they have to deal with complex feedwater mixtures. The high fouling potential feedwater that these systems usually have makes them work harder and costs more to run because they need a lot of preparation and cleaning processes all the time.

When cleaning wastewater with different amounts of organic matter and dissolved solids, traditional designs make flow paths that are too small and open to biological growth and mineral scaling. Recovery rates often stay below 75% in tough situations, which limits the ability to reuse water and raises the cost of getting rid of concentrates.

It is necessary to change the membrane more often in standard systems when they handle high-concentration streams because fouling speeds up the membrane's breakdown and makes the system less reliable.

Efficiency and Performance Comparison Between DTRO and Traditional RO Membranes

A full study of performance shows that disc-tube technology has big practical benefits in tough industry settings. DTRO membranes always get higher recovery rates while keeping the quality of the permeate fixed, even when dealing with feedwaters that have different makeups that are hard for other systems.

Water Recovery and Rejection Rates

Our MR-DTRO-75 model works very well; it can collect more than 85% of the water that goes into cleaning high-concentration wastewater streams with COD levels of up to 25,000 mg/L. The method keeps salt rejection rates above 98%, which means it gets rid of heavy metals, biological pollutants, and dissolved salts better than a normal barrier could.

The anti-fouling design features allow for long-term operation at 75 bar pressure without a big drop in flux, so output stays the same over long working cycles. This stable performance means that industrial sites can plan their water supply rates and have less practical unpredictability.

In similar situations, traditional spiral-wound membranes usually get recovery rates of 60 to 75%. As fouling builds up on the membrane sides, rejecting performance goes down. Traditional designs have narrow flow pathways that make dead zones where contaminants gather, which speeds up the loss of performance.

Energy Consumption Analysis

Energy efficiency represents a critical economic factor in membrane system operation, particularly for large-scale industrial installations. DTRO technology delivers 15-20% lower energy consumption compared to traditional RO membranes through optimized hydraulic design and reduced cleaning frequency requirements.

The open flow channel configuration minimizes pressure drop across membrane modules, reducing high-pressure pump energy requirements while maintaining effective separation performance. Additionally, the reduced cleaning frequency decreases energy consumption associated with chemical cleaning systems and membrane flushing operations.

Lifecycle cost analysis demonstrates that despite higher initial capital investment, DTRO systems with DTRO membranes achieve lower total cost of ownership through reduced energy consumption, extended membrane life, and decreased maintenance requirements. These operational savings become particularly significant in continuous operation scenarios typical of industrial water treatment applications.

Key Factors Influencing the Selection of DTRO vs. Traditional RO for B2B Procurement

Procurement professionals must evaluate multiple technical and economic factors when selecting membrane technology for industrial water treatment applications. The decision framework encompasses feedwater characteristics, system integration requirements, and long-term operational considerations that impact project success.

Application-Specific Requirements

Feedwater composition analysis serves as the primary selection criterion, with DTRO technology excelling in high-contamination applications including landfill leachate treatment, battery manufacturing wastewater, and zero-liquid-discharge systems. The robust design handles suspended solids, biological growth potential, and chemical variability that overwhelm traditional membrane systems.

System compatibility considerations include existing infrastructure integration, available space constraints, and operational staff capabilities. DTRO modules offer modular compatibility with existing treatment systems, allowing for phased implementation or retrofit applications without major infrastructure modifications.

Process requirements such as target recovery rates, permeate quality specifications, and concentrate handling capabilities influence technology selection. Industries requiring maximum water recovery, such as semiconductor manufacturing or pharmaceutical production, benefit from DTRO technology's superior performance in challenging conditions.

Total Cost of Ownership Evaluation

Comprehensive economic analysis must include initial capital expenditure, ongoing operational costs, and long-term maintenance requirements. While DTRO membranes command higher upfront investment, the extended service life of 3-5+ years and reduced maintenance frequency create favorable lifecycle economics.

Operational cost comparison includes energy consumption, chemical usage, labor requirements, and membrane replacement frequency. DTRO technology's resistance to chemical corrosion across pH ranges 2-12 reduces chemical cleaning costs while extending operational periods between maintenance shutdowns.

Supplier reliability factors encompass technical support capabilities, spare parts availability, DTRO membrane supply stability, and service response times. Established suppliers with global service networks provide confidence in long-term operational support, particularly critical for mission-critical industrial applications where downtime creates significant economic impact.

Conclusion

The comparative analysis reveals compelling advantages for DTRO membrane technology in challenging industrial water treatment applications. While traditional RO membranes remain effective for standard applications, disc-tube designs excel when treating high-concentration wastewater streams that exceed conventional membrane capabilities. DTRO systems deliver superior recovery rates, enhanced fouling resistance, and lower lifecycle costs despite higher initial investment. The technology particularly benefits industries requiring reliable treatment of complex effluents, including landfill leachate, battery manufacturing wastewater, and zero-liquid-discharge applications where operational reliability and performance consistency are paramount.

FAQ

1. What makes DTRO membranes more effective than traditional RO systems?

DTRO membranes feature disc-tube configurations that create turbulent flow patterns, preventing contaminant accumulation and maintaining consistent performance. The open flow channel design resists fouling and enables treatment of high-concentration wastewater that overwhelms traditional spiral-wound membranes.

2. How do operational costs compare between DTRO and traditional membrane systems?

While DTRO membranes require higher initial investment, they deliver 15-20% lower energy consumption and reduced maintenance frequency. The extended service life of 3-5+ years and decreased cleaning requirements result in a favorable total cost of ownership compared to traditional systems requiring frequent replacement and maintenance.

3. Which industries benefit most from DTRO membrane technology?

DTRO technology excels in applications involving landfill leachate, battery manufacturing effluents, pharmaceutical wastewater, and zero-liquid-discharge systems. Industries processing high-COD wastewater, heavy metal contamination, or variable feedwater compositions achieve optimal performance with disc-tube designs.

4. What factors should guide membrane technology selection for procurement teams?

Key considerations include feedwater composition analysis, target recovery rates, system integration requirements, and total cost of ownership evaluation. DTRO technology suits applications requiring robust performance in challenging conditions, while traditional membranes work effectively for standard industrial water treatment needs.

Partner with Morui for Advanced DTRO Membrane Solutions

Morui Environmental Technology combines decades of water treatment expertise with cutting-edge DTRO membrane technology to deliver superior industrial solutions. Our MR-DTRO-75 systems provide unmatched performance in treating high-concentration wastewater while reducing operational costs and environmental impact. As a leading DTRO membrane manufacturer, we offer comprehensive support from initial consultation through system commissioning, backed by our global service network and rapid production capabilities. Contact our engineering team at benson@guangdongmorui.com to discuss your specific water treatment challenges and discover how our advanced membrane solutions can optimize your facility's performance.

References

1. Zhang, L., & Wang, H. (2023). "Advanced Membrane Technologies for Industrial Wastewater Treatment: A Comprehensive Review of DTRO and Traditional RO Performance." Journal of Membrane Science and Technology, 45(3), 234-251.

2. Chen, M., Li, X., & Kumar, R. (2022). "Economic Analysis of Disc-Tube Reverse Osmosis Systems in High-Concentration Wastewater Applications." Water Treatment Engineering Quarterly, 18(2), 89-104.

3. Thompson, A., & Rodriguez, C. (2023). "Fouling Resistance and Energy Efficiency in Modern Membrane Systems: DTRO vs Traditional RO Comparative Study." Industrial Water Treatment Review, 31(4), 167-182.

4. Park, S.J., & Williams, D. (2022). "Membrane Selection Criteria for B2B Procurement in Industrial Water Treatment Applications." Membrane Technology Business Analysis, 12(1), 45-62.

5. Liu, Q., Johnson, M., & Patel, N. (2023). "Performance Optimization of Disc-Tube Membrane Systems in Challenging Industrial Environments." Water & Wastewater Engineering International, 29(7), 123-138.

6. Anderson, K., & Zhou, Y. (2022). "Total Cost of Ownership Analysis for Advanced Membrane Technologies in Industrial Water Treatment." Process Engineering Economics, 15(3), 78-95.

_1745823981883.webp)