Best Container Sewage Treatment Plants for Kenya Industrial Zones

Businesses looking for the best container sewage treatment plants for Kenya's quickly growing industrial zones require effective, compact solutions that tackle challenging wastewater issues. For manufacturing facilities, pharmaceutical companies, food processing plants, and other industrial operations needing dependable effluent treatment while maximizing operational flexibility and minimizing environmental impact, container-based commercial sewage treatment plant systems provide modular, transportable designs.

Introduction

Kenya's industrial landscape is expanding at a rate never seen before, posing significant operational and environmental problems to manufacturing plants in a variety of industries. Innovative wastewater treatment technologies that can adjust to changing production demands while upholding stringent environmental compliance criteria are necessary for the growth of industrial parks and special economic zones.

When compared to conventional fixed installations, commercial sewage treatment plant containerized sewage treatment plants offer unparalleled flexibility, making them revolutionary solutions for industrial wastewater management. These modular systems offer scalable treatment capacity that increases with the needs of business expansion while addressing the particular limitations faced by industrial establishments operating within constrained space allowances.

Purchasing managers, plant engineers, distributors, and OEM clients looking for useful information on container-based treatment technologies are the target audience for this extensive guide. We assist decision-makers in navigating the complicated terrain of contemporary wastewater treatment investments by examining technical specifications, operational advantages, procurement concerns, and maintenance requirements, especially suited to Kenya's industrial environment.

Understanding Container Sewage Treatment Plants and Their Industrial Relevance

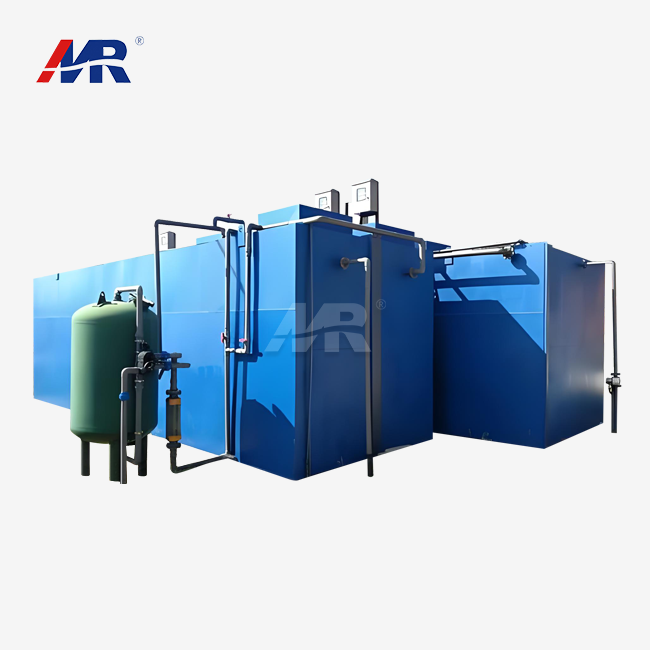

Advanced wastewater treatment technologies are included in standardized shipping containers in container sewage treatment plants, which create fully integrated treatment facilities that are portable and quickly deployable. These systems combine advanced physical, chemical, and biological treatment procedures in small, weatherproof enclosures made for industrial use.

Modular Design and Deployment Advantages

Containerized systems provide exceptional deployment flexibility in contrast to conventional concrete-based treatment facilities. All required parts, including pumps, aerators, control systems, and monitoring apparatus, are pre-assembled when each unit is delivered. This design strategy minimizes interference with ongoing industrial processes by cutting the installation period from months to weeks.

Precise capacity matching for particular commercial sewage treatment plant industrial needs is made possible by the modular architecture. Manufacturing facilities can start with single-container units that can handle 50–100 cubic meters per day, and as production demands rise, they can add more modules to enhance capacity. For expanding industrial operations or seasonal production facilities, this scalability proves very advantageous.

Advanced Treatment Technologies

Membrane bioreactor (MBR) technology is used in modern container plants to obtain higher effluent quality by combining membrane filtration and biological treatment. Activated sludge systems are used in the biological treatment process, where microorganisms break down organic contaminants before ultrafiltration membranes remove pathogens and suspended particles.

Preliminary screening and grit removal, primary sedimentation, AAO biological treatment, MBR membrane filtration, and final disinfection phases are all included in the treatment workflow. This all-encompassing strategy guarantees that treated wastewater satisfies strict discharge regulations while opening up possibilities for water reuse in irrigation or industrial cooling applications.

Key Benefits and Operational Insights for Industrial B2B Clients

Container-based wastewater treatment systems deliver compelling advantages that align perfectly with modern industrial operational requirements. These benefits extend beyond simple space savings to encompass operational efficiency, regulatory compliance, and long-term cost management considerations.

Operational Excellence and Space Optimization

Here are the core advantages these systems deliver for industrial operations:

- Compact Footprint: Container plants are perfect for industrial zones with limited space, where land prices are still a major concern because they take up 30% less room than traditional treatment systems.

- Quick Implementation: Prefabricated design minimizes production disturbance during implementation phases by allowing installation in 2-4 weeks as opposed to 6-12 months for standard systems.

- Automated Operation: By managing treatment procedures automatically, advanced control systems lower labor costs while preserving treatment performance under a range of influent circumstances.

- Modular Expansion: Without investing in a full system replacement, more treatment capacity can be added gradually by connecting many containers.

These operational advantages directly address the challenges industrial facilities face when balancing treatment requirements with operational efficiency and cost management objectives.

Maintenance and Compliance Considerations

Long-term system dependability is ensured by efficient maintenance procedures in a commercial sewage treatment plant that adheres to Kenya's environmental regulations. Maintaining automated control systems, confirming biological process performance, and assessing membrane integrity are examples of routine monitoring. While shielding delicate equipment from the elements, the containerized design makes maintenance access easier.

Regular monitoring and reporting of effluent quality is necessary to comply with Kenya's National Environment Management Authority (NEMA) regulations. Automated monitoring systems installed in container plants streamline compliance paperwork and offer real-time notifications of treatment parameter variations that could compromise discharge quality.

Comparative Analysis of Container Sewage Treatment Solutions for Industrial Procurement

Procurement professionals evaluating container treatment systems must consider multiple factors affecting long-term value and operational effectiveness. Performance capabilities, cost structures, and service support vary significantly among solution providers, making a thorough evaluation essential for optimal investment decisions.

Performance and Technology Comparison

In all important treatment parameters, container systems outperform traditional package plants in performance measures. Whereas COD reduction is 85–90% successful, BOD removal efficacy usually surpasses 95%. Advanced membrane filtration achieves 99% efficiency in suspended particles removal, guaranteeing constant discharge quality despite influent fluctuations.

One of the most important operational cost factors is energy use in a commercial sewage treatment plant. Compared to earlier treatment systems, modern container plants use substantially less energy—0.5–0.8 kWh per cubic meter treated. Energy-efficient pumps, automated control systems that modify operations in response to real treatment loads, and optimized aeration systems are the main contributors to this efficiency.

Cost Structure Analysis

Investment costs for container treatment systems vary based on capacity requirements and treatment specifications. Initial capital investment typically ranges from $100,000 to $500,000 for systems handling 50-500 cubic meters daily. This investment includes equipment, installation, commissioning, and initial operator training.

Operational costs encompass electricity consumption, membrane replacement, chemical additives, and routine maintenance services. Annual operational expenses typically represent 8-12% of initial capital investment, providing predictable cost structures for long-term budgeting purposes. The modular design enables staged capacity expansion, allowing organizations to match investment timing with revenue growth patterns.

Manufacturer Evaluation Criteria

Leading manufacturers differentiate themselves through technical innovation, service quality, and warranty provisions. Established providers offer comprehensive service packages including installation supervision, operator training, remote monitoring capabilities, and preventive maintenance programs. Warranty terms typically cover equipment for 1-2 years, with membrane warranties extending 3-5 years under normal operating conditions.

Service network availability within Kenya affects long-term operational success. Manufacturers with local service partnerships provide faster response times for maintenance issues while ensuring spare parts availability through regional distribution networks.

Company Introduction and Product & Service Information

Guangdong Morui Environmental Technology Co., Ltd. specializes in comprehensive water treatment solutions designed specifically for industrial applications across diverse sectors. Our expertise in commercial sewage treatment plant technologies encompasses containerized systems engineered to meet the demanding requirements of manufacturing facilities, pharmaceutical companies, food processing operations, and other industrial clients.

Advanced Container Treatment Solutions

Our state-of-the-art container treatment systems utilize advanced membrane bioreactor technology to handle complex wastewater challenges faced by modern industrial operations. These systems deliver superior effluent quality with impressive performance specifications, including BOD removal efficiency exceeding 95%, COD reduction above 85%, and suspended solids removal reaching 99% effectiveness.

The modular design offers treatment capacities ranging from 50 to 10,000 cubic meters daily, accommodating everything from small manufacturing facilities to large industrial complexes. Power consumption remains optimized at 0.5-0.8 kWh per cubic meter, while the compact footprint saves 30% space compared to conventional treatment systems.

Comprehensive Service Capabilities

Our service portfolio extends beyond equipment supply to encompass complete project lifecycle support. We provide one-stop installation and commissioning services, ensuring seamless system integration with existing industrial operations. Our team of 20 experienced engineers collaborates with clients throughout the design, implementation, and optimization phases.

With 14 branches and 500 employees across our organization, we maintain manufacturing capabilities, including our own membrane production factory and multiple equipment processing facilities. This vertical integration ensures quality control while enabling customization for specific industrial requirements. Our partnerships with leading component suppliers, including Shimge Water Pumps, Runxin Valves, and Createc Instruments, provide access to premium-grade components for enhanced system reliability.

Future Trends and Performance Optimization in Container Sewage Treatment

The evolution of container-based wastewater treatment continues advancing through technological innovation and operational optimization strategies. These developments promise enhanced efficiency, reduced environmental impact, and improved cost-effectiveness for industrial applications across Kenya's expanding industrial sectors.

Emerging Technology Integration

Automation and remote monitoring capabilities transform container treatment operations by enabling real-time performance tracking and predictive maintenance scheduling. Internet-of-Things sensors monitor key parameters including flow rates, treatment efficiency, and equipment performance, providing operators with comprehensive system visibility from centralized control rooms.

Artificial intelligence algorithms analyze operational data to optimize commercial sewage treatment plant treatment processes automatically, adjusting aeration rates, chemical dosing, and membrane cleaning cycles based on influent characteristics and treatment objectives. This optimization reduces energy consumption while maintaining consistent effluent quality across varying operational conditions.

Sustainability and Circular Economy Applications

By facilitating the use of water reuse in industrial processes, container treatment systems make a substantial contribution to the concepts of the circular economy. For landscape irrigation, equipment cleaning, and cooling systems, treated wastewater can be used in place of fresh water, lowering overall water use and minimizing environmental discharge quantities.

By capturing biogas from anaerobic treatment processes, energy recovery systems can integrate with facility power systems or provide renewable energy for system operations. By lowering operating carbon emissions and increasing energy independence, solar panel integration complies with legal standards and company sustainability goals.

Conclusion

When compared to conventional treatment methods, container sewage treatment plants offer unparalleled flexibility, performance, and cost-effectiveness, making them the ideal choice for Kenya's changing industrial landscape. For industrial enterprises looking for dependable, scalable wastewater treatment solutions, the combination of cutting-edge MBR technology, modular architecture, and extensive service support produces attractive value propositions. Container-based systems offer the flexibility required to fulfill increasing environmental compliance standards and promote sustainable industrial development goals across various manufacturing sectors as Kenya's industrial zones continue to grow.

FAQ

Q1: What capacity range is available for industrial container treatment systems?

Container treatment systems accommodate industrial requirements ranging from 50 cubic meters daily for small manufacturing facilities up to 10,000 cubic meters daily for large industrial complexes. Modular design enables capacity expansion by connecting multiple units, providing scalable solutions that grow with business expansion needs.

Q2: How do container plants ensure compliance with Kenya's environmental regulations?

Modern container systems incorporate automated monitoring equipment that tracks effluent quality parameters required by NEMA standards. Real-time data logging provides documentation for regulatory reporting, while automated alerts notify operators of any parameter deviations requiring corrective action.

Q3: What maintenance requirements should industrial facilities expect?

Routine maintenance includes weekly visual inspections, monthly membrane cleaning cycles, and quarterly comprehensive system checks. Professional servicing requirements typically occur every 6-12 months, depending on operational loads. The containerized design simplifies maintenance access while protecting equipment from environmental exposure.

Q4: How quickly can container treatment systems be installed and commissioned?

Container systems typically require 2-4 weeks for complete installation and commissioning compared to 6-12 months for traditional treatment facilities. The pre-fabricated design minimizes site preparation requirements while reducing installation complexity and associated production disruption.

Morui Commercial Sewage Treatment Plant Solutions

Morui Environmental Technology stands ready to transform your industrial wastewater management through cutting-edge container treatment solutions. Our commercial sewage treatment plant supplier expertise delivers customized systems engineered specifically for Kenya's industrial requirements, combining proven MBR technology with modular flexibility to optimize treatment performance while minimizing operational costs. Partner with our experienced engineering team to explore how our advanced container systems can enhance your facility's environmental compliance and operational efficiency. Contact benson@guangdongmorui.com to schedule your consultation and discover comprehensive solutions tailored to your industrial wastewater treatment needs. Visit moruiwater.com to explore our complete product portfolio and service capabilities designed for industrial excellence.

References

1. Kenya Association of Manufacturers. "Industrial Wastewater Management Guidelines for Manufacturing Facilities." Industrial Environmental Standards Publication, 2023.

2. National Environment Management Authority Kenya. "Effluent Discharge Standards for Industrial Facilities." Environmental Compliance Framework, 2022.

3. East Africa Industrial Development Report. "Container-Based Treatment Technologies for Emerging Markets." Regional Infrastructure Development Studies, 2023.

4. International Water Association. "Membrane Bioreactor Technology Applications in Industrial Wastewater Treatment." Technical Innovation Review, 2023.

5. Kenya Bureau of Standards. "Industrial Zone Development and Environmental Infrastructure Requirements." Infrastructure Planning Guidelines, 2022.

6. African Development Bank. "Sustainable Industrial Development and Water Resource Management in East Africa." Regional Development Assessment, 2023.

_1745823981883.webp)