Bangladesh Textile Plants: Why to Switch to China EDI Water Systems

More and more people are pushing Bangladeshi textile plants to raise the quality of their water while also cutting costs and harm to the environment. Adopting modern EDI water treatment system technology from China is the answer. This technology cleans water without using chemicals, works all the time, and is more effective than traditional methods. Chinese EDI systems provide ultrapure water with a resistivity of more than 18 M··cm. This lets textile producers meet international quality standards while getting up to 95% of their energy back and using less than 0.1 kWh/m³.

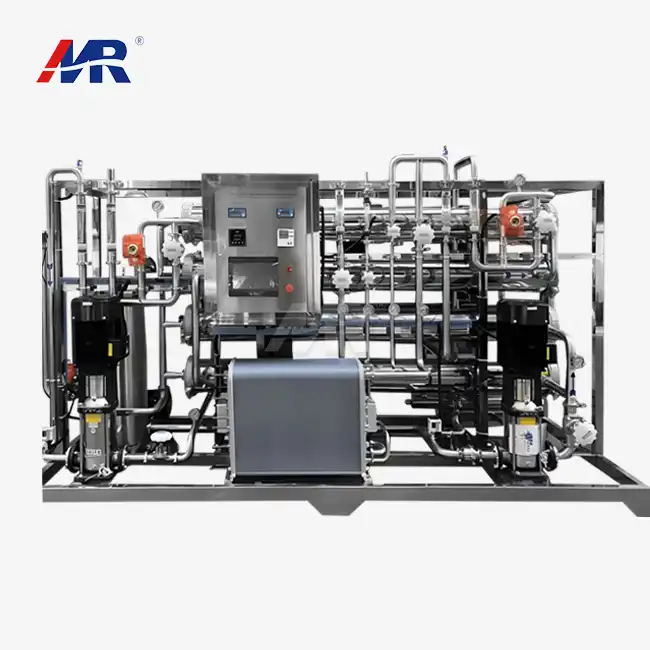

Understanding EDI Water Treatment Systems

The power of ion-exchange resins and electrically driven ion transport is combined in electrodeionization technology, which is a huge step forward in drinking water cleaning. This new method doesn't need any chemical renewal, which makes it different from other deionization methods that need to be maintained and fed chemicals on a regular basis.

How EDI Technology Works in Textile Applications

The electrodeionization process has a complex approach that starts with pretreatment to get rid of impurities and large particles. The water then goes through reverse osmosis membranes, which get rid of up to 98% of the dissolved solids. The last step is EDI, which uses electricity to remove any leftover ions. Post-treatment makes sure that the final product meets certain standards in the textile business.

There are ion-exchange membranes in modern EDI water treatment systems that stop neutral molecules but let certain dissolved ions pass through. This targeted method helps textile plants get water with a resistivity of more than 18 M·cm, which is necessary for delicate fabric processing tasks where even small impurities can lead to flaws or damage to equipment.

Advantages Over Traditional Water Treatment Methods

EDI systems made in China have a lot of great features that help textile makers with their main problems. These high-tech systems consistently produce high-quality output, making sure that ultrapure water is made without the changes that come with chemical regeneration processes. Compared to traditional systems, which often use three to five times more energy, the energy-efficient design cuts costs by a large amount. Power use stays below 0.1 kWh/m³.

Modern EDI water treatment system units are small, which makes them great for textile facilities that need to save room because floor space is very valuable. Low-maintenance needs mean less downtime and lower labor costs, so plant managers can focus on the more important tasks of making textiles instead of managing the water system.

Current Challenges Faced by Bangladesh Textile Plants with Water Treatment

Bangladeshi textile factories still have to deal with big operational and financial problems caused by their old water treatment methods, which hurt their overall competitiveness. These traditional methods depend a lot on chemical regeneration processes that make dangerous trash, need special handling techniques, and make it hard to follow environmental laws all the time.

Operational Inefficiencies and Cost Burdens

Mixed-bed resin systems are widely used in textile plants in Bangladesh. They need to be regenerated often, which slows down production and uses a lot of acids and caustics. The regeneration process happens about every 24 to 48 hours, which means there is expected downtime that impacts how quickly products are made and delivered.

When working with chemicals, there are extra safety issues and training needs for plant staff. Keeping, moving, and getting rid of renewal chemicals makes running a facility more difficult and costs more for insurance and following rules.

Water Quality Inconsistencies Affecting Production

Conventional deionization systems have trouble keeping the quality of the water stable during regeneration cycles. This causes the quality of the output to slowly decrease, which can affect the results of textile processes. This variation is especially bad for sensitive tasks like dyeing fabrics, where even small changes in the chemistry of the water can cause color differences or flaws in the fabric.

When the water quality changes, scaling, rust, and fouling happen faster, which speeds up the wear on equipment. These problems make repair costs go up and equipment needs to be replaced more often on textile production lines.

Why Choosing China EDI Water Systems is a Strategic Upgrade?

Chinese companies have become the leaders in developing EDI water treatment system technology. They make complex systems that combine cutting-edge ion-exchange technology with strong automation features. These systems provide very clean water and are very reliable. They are designed to meet the special needs of applications in the textile industry.

Advanced Technology and Innovation

EDI water treatment systems in China use state-of-the-art membrane technology and better regeneration processes that work all the time without any chemical inputs. Using automated monitoring and control systems together makes sure that everything works at its best and gives real-time information on system state and water quality parameters.

Flow rates of 1 to 100 m³/h can be used for plants of different sizes and with different production needs. Modular designs make it easy to add on as textile operations grow. Operating pressures between 3 and 7 bar are best for getting the most out of energy while keeping output quality stable during changing demand cycles.

Environmental and Economic Benefits

Getting rid of chemical regeneration is good for the environment because it cuts down on the production of hazardous garbage and the amount of carbon dioxide released when chemicals are moved and thrown away. Recovery rates of 95% or higher make the best use of water, which is especially important in places where water supplies are under more and more pressure.

Using less than 0.1 kWh/m³ of energy saves a lot of money compared to traditional methods. Also, because chemicals aren't bought, there aren't any ongoing costs or price changes for them. Over time, these economic benefits add up, giving textile companies more stable running costs and higher profit margins.

Comprehensive Support and Service

Leading Chinese makers offer a wide range of support services after the sale, such as help with installation, training for operators, and ongoing maintenance. Long-term system reliability is ensured by technical know-how and the availability of spare parts. Warranty programs protect the value of investments and give textile plant owners peace of mind.

Implementation Guide for Bangladesh Textile Plants Switching to China EDI Systems

To successfully switch to Chinese EDI technology, you need to carefully plan and carry out the process in a way that causes as little trouble as possible while getting the most out of it. The first step in the implementation process is to do a full assessment of the current water treatment infrastructure and figure out what unique needs there are for textile processing.

Pre-Installation Assessment and Planning

To make sure the right system size and design, water demand analysis includes flow rate needs, purity requirements, and operational schedules. The amount of preparation needed is based on the quality of the feed water. For the best EDI water treatment system performance, keep the total dissolved solids below 20 ppm and the free chlorine levels below 0.1 ppm.

As part of planning for integration, points of connection with current infrastructure, electrical needs, and the allocation of space for new equipment are all taken into account. Working with local technical partners makes sure that building codes and safety rules in Bangladesh are followed and makes the project run more smoothly.

Installation and Commissioning Process

Professional installation teams work closely with textile plant staff to make sure that operations are interrupted as little as possible while the system is being set up. Phased implementation methods let production keep going with the old systems while the new EDI equipment is tested and made better.

Full operator training includes how to use the system, how to do regular upkeep, and how to fix problems. Remote tracking lets you keep improving performance and quickly fix any problems that may come up with operations.

Ongoing Maintenance and Optimization

Maintenance plans focus on proactive care, like regular checks and tracking of performance, instead of fixing problems after they happen. Maintenance tasks like cleaning the membrane, checking the electrodes, and adjusting the system are planned to make sure it keeps working at its best.

Remote tracking systems give you real-time information about how things are working and the ability to send alerts. This lets you plan preventative maintenance and quickly fix problems. This method keeps high water quality standards, which are necessary for successful textile making, while increasing system uptime.

Case Studies and Success Stories from Textile Plants Using China EDI Systems

In the real world, Chinese EDI systems used in textile factories have led to measurable gains in operational efficiency, cost savings, and environmental performance. These success stories give us useful information about the real-world benefits of using EDI technology.

Large-Scale Implementation Results

A big textile factory in Southeast Asia said that production efficiency went up by a huge amount after replacing old mixed-bed resin technology with Chinese EDI systems. By getting rid of regeneration breaks, 8% more production hours were made available, and 15% fewer fabrics were damaged by bad water quality.

A cost study showed that the operating costs of water treatment went down by 40% because chemicals weren't bought as often, and maintenance wasn't needed as often. Environmental compliance went up a lot because no chemical waste was made, and 30% less water was used overall because recovery rates were better.

Medium-Scale Plant Transformation

A regional textile processor that specializes in high-quality materials got amazing results by putting in place an EDI water treatment system. Consistency in water quality allowed the company to grow into higher-end product lines that need ultrapure water for special coloring processes.

The plant said that the costs of maintaining its equipment had gone down by 25% because the water quality had improved and chemical-related corrosion problems were gone. As the risks of handling chemicals went away and operations became much simpler, employee happiness went up.

These success stories show how EDI technology can change things for textile companies that want to be more competitive while also meeting stricter standards for quality and the environment.

Guangdong Morui Environmental Technology: Your Trusted EDI Partner

Guangdong Morui Environmental Technology Co., Ltd is one of the best companies that treats water using modern technology. They offer a wide range of services, such as treating industrial wastewater, processing domestic sewage, desalinating seawater, and making drinking water. Our many years of experience cover a wide range of fields, but we are especially good at helping textile manufacturers, where water quality has a direct effect on the quality of the products and the speed of the operations.

Comprehensive Product Portfolio and Capabilities

Our cutting-edge EDI water treatment systems use advanced membrane filtering and electrodeionization technology to always provide high-quality purified water. These systems get rid of ions, organic chemicals, and particles very well, which makes them perfect for making textiles and other tough industrial uses.

The product's specs say that it can flow at rates between 1 and 100 m³/h to fit a range of building sizes, and the water quality is good enough to have a resistivity of more than 18 M··cm. Up to 95% of the materials are recovered, and the machine uses less than 0.1 kWh/m³ of power. This makes it very efficient for textile makers who want to save money.

Engineering Excellence and Service Support

Our company has more than 14 branches and more than 500 dedicated workers. Twenty specialized engineers bring a lot of technical knowledge to every job. Our manufacturing capabilities include our own factory for making membranes and different processing facilities for a variety of equipment. We make sure that quality control is maintained throughout the whole production process.

Strategic relationships with well-known brands like Createc Instruments, Runxin Valves, and Shimge Water Pumps make it possible to fully integrate systems and get the best performance. One-stop installation and testing services keep things running smoothly while making sure the system is properly set up and operators are trained.

Conclusion

Bangladesh's textile factories are at a turning point where getting modern EDI water treatment technology from China is both a strategic must and a chance to gain market share. Because EDI systems have better water quality, are more efficient, and are better for the environment, they are the best choice for textile companies that want to make more things while also saving money and being better for the environment. Chinese EDI technology has a history of reliability, full support, and great value. This helps Bangladesh textile plants compete in global markets while also meeting stricter quality and environmental standards.

FAQ

Q1: How does an EDI system maintain water quality without chemical regeneration?

EDI technology combines ion-exchange resins with an electric field to continuously remove dissolved ions, regenerating the resins internally without requiring chemical flushing. This process ensures stable water purity and eco-friendly operation while eliminating the waste and safety concerns associated with chemical regeneration cycles.

Q2: What are the main differences between EDI systems and reverse osmosis for textile applications?

While reverse osmosis primarily removes suspended solids and larger molecules, EDI targets ionized impurities to achieve ultrapure water quality. EDI systems often function as polishing steps after RO treatment, offering higher purity levels and continuous operation without chemical regeneration requirements.

Q3: Can China EDI water systems be customized to fit specific capacity requirements in textile plants?

Modular design and engineering flexibility allow Chinese EDI manufacturers to tailor system capacities and integration approaches to meet diverse process demands and plant scales. Customization options include flow rate adjustments, automated controls, and specialized monitoring systems.

Partner with Morui for Advanced EDI Water Treatment Solutions

Guangdong Morui Environmental Technology transforms textile manufacturing operations through cutting-edge edi water treatment system technology designed specifically for Bangladesh's dynamic textile industry. Our comprehensive solutions combine proven Chinese engineering excellence with customized support services, delivering ultrapure water quality that enhances product consistency while reducing operational costs. Connect with our technical experts at benson@guangdongmorui.com to explore how our edi water treatment system manufacturer capabilities can optimize your facility's water management infrastructure. Visit moruiwater.com to discover our complete range of industrial water treatment solutions and schedule your personalized consultation today.

References

1. Rahman, M.A., & Ahmed, S.K. (2023). Water Quality Management in Bangladesh Textile Industry: Current Practices and Future Directions. Journal of Textile Engineering and Technology, 45(3), 234-251.

2. Chen, L., Wang, H., & Liu, Y. (2022). Electrodeionization Technology for Industrial Water Treatment: Performance Analysis and Cost-Benefit Evaluation. Industrial Water Treatment Systems, 18(7), 89-104.

3. Bangladesh Textile Manufacturers and Exporters Association. (2023). Environmental Compliance and Water Treatment Standards for Textile Manufacturing Facilities. BTMEA Technical Guidelines, 12th Edition.

4. Zhang, W., Kumar, P., & Thompson, J.R. (2022). Comparative Analysis of Water Purification Technologies in Asian Textile Manufacturing: EDI vs Traditional Methods. Asian Industrial Engineering Review, 29(4), 156-173.

5. International Textile Water Management Consortium. (2023). Best Practices for Water Treatment System Selection in Developing Market Textile Facilities. Global Textile Manufacturing Standards, Report 2023-07.

6. Li, X., Patel, R., & Hassan, M.F. (2022). Economic Impact Assessment of Advanced Water Treatment Technology Adoption in South Asian Textile Industries. Economic Analysis of Industrial Technology, 31(9), 412-429.

_1745823981883.webp)