How Semipermeable Membranes Work?

Semipermeable membranes are the cornerstone of reverse osmosis technology. These sophisticated barriers exhibit selective permeability, allowing certain molecules or ions to pass through while blocking others. In the context of RO systems, the membrane is designed to permit water molecules to traverse its structure while impeding the passage of larger particles, dissolved salts, and other contaminants.

The Structure of RO Membranes

The typical Reverse Osmosis Membrane consists of multiple layers, each serving a specific purpose: 1. A thin active layer, usually made of polyamide, which performs the actual separation 2. A porous support layer, often composed of polysulfone, providing structural integrity 3. A fabric backing for additional strength and durability This layered structure allows the membrane to withstand high pressures while maintaining its selective filtration properties. The active layer contains pores so small they're measured in angstroms, enabling the separation of water molecules from dissolved solids and other impurities.

Molecular-Level Filtration

At the molecular level, the semipermeable membrane functions through a combination of size exclusion and charge repulsion. Water molecules, being smaller than most contaminants, can pass through the membrane's pores. Meanwhile, larger molecules, ions, and particles are blocked based on their size or electric charge. This selective permeability is what makes RO membranes so effective at producing high-purity water.

Pressure and Osmotic Balance Explained

The driving force behind reverse osmosis is pressure – specifically, the pressure required to overcome natural osmotic pressure and force water through the semipermeable membrane. Understanding this balance is crucial to grasping the efficiency and effectiveness of RO membranes systems.

Osmotic Pressure and Its Reversal

In nature, osmosis occurs when water moves from an area of lower solute concentration to an area of higher concentration across a semipermeable membrane. This movement creates osmotic pressure. Reverse osmosis, as the name suggests, reverses this natural process by applying external pressure that exceeds the osmotic pressure. This applied pressure forces water to move from the more concentrated solution (feed water) to the less concentrated solution (permeate), effectively purifying the water.

The Role of Pressure in RO Systems

The amount of pressure required in an RO system depends on several factors, including the concentration of dissolved solids in the feed water and the desired recovery rate. Typically, RO systems operate at pressures ranging from 50 to 1000 psi (3.4 to 68 bar). This pressure not only overcomes osmotic pressure but also drives water through the membrane at a rate that makes the process economically viable for large-scale applications.

Innovations in Membrane Material Technology

The field of membrane technology is continuously evolving, with researchers and engineers developing new materials and structures to enhance the performance and efficiency of RO systems.

Advanced Membrane Materials

Recent innovations in membrane materials have led to significant improvements in flux rates, salt rejection, and fouling resistance. Some notable advancements include: 1. Graphene-based membranes: Offering extremely high water permeability while maintaining excellent salt rejection 2. Nanocomposite membranes: Incorporating nanoparticles to enhance membrane properties and performance 3. Biomimetic membranes: Inspired by natural biological processes, these membranes aim to replicate the high efficiency of cellular water channels

Surface Modification Techniques

Surface modification of RO membranes has emerged as a powerful tool to enhance their performance and longevity. Techniques such as plasma treatment, grafting, and coating are being employed to: 1. Increase hydrophilicity, improving water flux 2. Enhance fouling resistance, reducing maintenance requirements 3. Improve chlorine tolerance, extending membrane lifespan These innovations are pushing the boundaries of what's possible with reverse osmosis technology, enabling more efficient and cost-effective water treatment solutions across various industries.

Conclusion

The science behind Reverse Osmosis Membrane filtration represents a remarkable convergence of physics, chemistry, and materials science. As we've explored, the interplay between semipermeable membranes, pressure dynamics, and cutting-edge material innovations forms the foundation of this powerful water purification technology. From municipal water treatment to industrial processes and beyond, RO continues to play a crucial role in addressing global water challenges.

For businesses and organizations seeking to implement or upgrade their water treatment systems, understanding the science behind RO is just the beginning. The next step is finding a reliable partner with the expertise and technology to deliver tailored solutions.

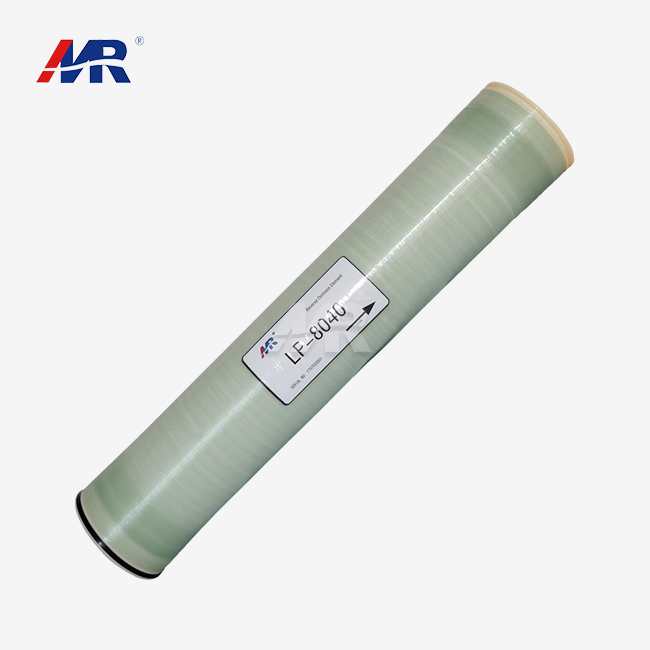

At Guangdong Morui Environmental Technology Co., Ltd, we specialize in providing top-tier water treatment solutions, including state-of-the-art reverse osmosis systems. Our comprehensive services cover industrial wastewater treatment, domestic sewage processing, seawater desalination, and drinking water manufacturing. With our own membrane production facility and equipment processing factories, we ensure the highest quality and performance in every system we deliver.

Whether you're in the manufacturing, food and beverage, pharmaceutical, or municipal sector, our team of expert engineers is ready to design and implement a reverse osmosis solution that meets your specific needs. We offer not just equipment, but a complete package including installation, commissioning, consumables, and comprehensive after-sales support.

Take the next step in advancing your water treatment capabilities. Contact us today at benson@guangdongmorui.com to discover how our innovative RO systems can transform your water purification processes. Let Guangdong Morui Environmental Technology Co., Ltd be your partner in achieving superior water quality and operational efficiency.

References

1. Baker, R. W. (2012). Membrane Technology and Applications. John Wiley & Sons.

2. Greenlee, L. F., et al. (2009). Reverse osmosis desalination: Water sources, technology, and today's challenges. Water Research, 43(9), 2317-2348.

3. Lee, K. P., Arnot, T. C., & Mattia, D. (2011). A review of reverse osmosis membrane materials for desalination—Development to date and future potential. Journal of Membrane Science, 370(1-2), 1-22.

4. Elimelech, M., & Phillip, W. A. (2011). The future of seawater desalination: Energy, technology, and the environment. Science, 333(6043), 712-717.

5. Werber, J. R., Osuji, C. O., & Elimelech, M. (2016). Materials for next-generation desalination and water purification membranes. Nature Reviews Materials, 1(5), 16018.

6. Pendergast, M. T. M., & Hoek, E. M. V. (2011). A review of water treatment membrane nanotechnologies. Energy & Environmental Science, 4(6), 1946-1971.

_1745823981883.webp)