Filtration Efficiency: A Side-by-Side Comparison

The filtration efficiency of reverse osmosis membranes and traditional filters varies significantly, primarily due to their fundamental operational differences. RO membranes operate on a molecular level, leveraging osmotic pressure to force water through a semi-permeable membrane. This process is remarkably effective at removing a wide spectrum of contaminants, including dissolved solids, heavy metals, and microorganisms.

Contaminant Removal Capabilities

Reverse osmosis systems boast an impressive contaminant removal rate, often exceeding 99% for many substances. They are particularly adept at eliminating:

- Dissolved salts and minerals

- Heavy metals like lead and mercury

- Microorganisms including bacteria and some viruses

- Organic compounds

Traditional filters, on the other hand, typically rely on physical straining or adsorption. While effective for certain contaminants, they often struggle with dissolved substances and smaller particles. Activated carbon filters, for instance, excel at removing chlorine and improving taste but are less effective against dissolved minerals or microorganisms.

Pore Size and Filtration Precision

The pore size of RO membranes is incredibly small, often measured in angstroms (Å). This allows for filtration at a near-molecular level, typically removing particles as small as 0.0001 micron. Traditional filters, depending on their type, have much larger pore sizes:

- Sediment filters: 5-20 microns

- Carbon block filters: 0.5-10 microns

- Ceramic filters: 0.2-0.5 microns

This substantial difference in pore size translates to a significant gap in filtration precision, with RO systems offering unparalleled purification capabilities.

Maintenance Requirements: RO vs. Traditional

Maintenance is a crucial aspect of any water filtration system, impacting both performance and longevity. The requirements for reverse osmosis membranes and traditional filters differ considerably, each presenting unique challenges and benefits.

Frequency of Replacement

Reverse osmosis membranes typically have a longer lifespan compared to most traditional filters. A well-maintained RO membrane can last 2-5 years, sometimes even longer in optimal conditions. This extended lifespan is partly due to the pre-filtration stages in most RO systems, which protect the membrane from larger particles and chlorine.

Traditional filters, however, often require more frequent replacements:

- Sediment filters: Every 3-6 months

- Carbon filters: Every 6-12 months

- Ceramic filters: Every 6-12 months, with regular cleaning

The more frequent replacement schedule of traditional filters can lead to higher long-term maintenance costs and increased labor requirements.

Cleaning and Sanitization

RO membranes require periodic cleaning and sanitization to maintain optimal performance. This process, known as membrane cleaning or Chemical Clean-In-Place (CIP), involves flushing the membrane with specialized cleaning solutions to remove fouling and scaling. While this process is more complex than replacing a traditional filter, it significantly extends the membrane's lifespan and maintains its high filtration efficiency.

Traditional filters generally don't require extensive cleaning procedures. However, some types, like ceramic filters, may need regular scrubbing to remove accumulated particles. The simplicity of maintaining traditional filters is often offset by their more frequent replacement needs.

System Complexity and Monitoring

Reverse osmosis systems are more complex, often incorporating multiple stages of filtration, including pre-filters, the RO membrane, and post-filters. This complexity necessitates more comprehensive monitoring and maintenance protocols. Parameters like feed water quality, pressure differentials, and permeate quality need regular checking to ensure optimal performance.

Traditional filtration systems are typically simpler, with fewer components to monitor and maintain. However, this simplicity can also mean less precise control over water quality and fewer indicators of when maintenance is necessary.

Choosing the Right System for Your Needs

Selecting between reverse osmosis membranes and traditional filters depends on various factors, including water quality requirements, application specifics, and operational constraints. Understanding these elements is crucial for making an informed decision that aligns with your water treatment goals.

Water Quality Requirements

The required water quality is perhaps the most critical factor in choosing between RO and traditional filtration:

- For high-purity applications like semiconductor manufacturing or pharmaceutical production, RO membranes are often the only viable option due to their superior contaminant removal capabilities.

- In less demanding scenarios, such as residential drinking water filtration in areas with generally good water quality, traditional filters might suffice and offer a more cost-effective solution.

Consider the specific contaminants you need to remove and the level of purity required. If you're dealing with high levels of dissolved solids or need to remove specific ions, RO is likely the better choice.

Flow Rate and Capacity Requirements

The volume of water you need to process is another crucial consideration:

- RO systems typically have lower flow rates compared to traditional filters but offer higher quality filtration.

- For high-volume applications, you might need to balance the superior filtration of RO with the higher flow rates of traditional systems, possibly by implementing larger or multiple RO units.

Assess your daily water usage and peak demand to determine which system can meet your capacity requirements efficiently.

Energy Consumption and Operational Costs

Reverse osmosis systems generally require more energy to operate due to the high pressure needed to force water through the membrane. This can lead to higher operational costs compared to traditional filters. However, advancements in membrane technology have significantly improved energy efficiency in recent years.

Traditional filters typically have lower energy requirements but may incur higher costs in terms of more frequent replacements and potentially less efficient contaminant removal.

Environmental Considerations

Both systems have environmental implications to consider:

- RO systems produce wastewater (reject water) as part of the filtration process. In water-scarce regions, this can be a significant concern.

- Traditional filters may require more frequent replacements, potentially generating more waste over time.

Consider implementing water recovery systems for RO or exploring recycling options for spent traditional filters to mitigate environmental impacts.

Regulatory Compliance

In industries with strict water quality regulations, such as food and beverage production or pharmaceutical manufacturing, RO systems often provide the level of purification necessary to meet compliance standards. Traditional filters may struggle to achieve the same level of purity consistently.

Review relevant industry standards and local regulations to ensure your chosen system can meet all necessary requirements.

Conclusion

In the comparison between reverse osmosis membranes and traditional filters, both systems have their place in water treatment. RO membranes excel in providing high-purity water and comprehensive contaminant removal, making them ideal for applications demanding stringent water quality. Traditional filters offer simplicity and can be effective for less demanding applications or as pre-treatment stages.

The choice ultimately depends on your specific needs, considering factors such as required water quality, operational constraints, and long-term costs. In many cases, a hybrid approach combining both technologies might provide the optimal solution, leveraging the strengths of each system.

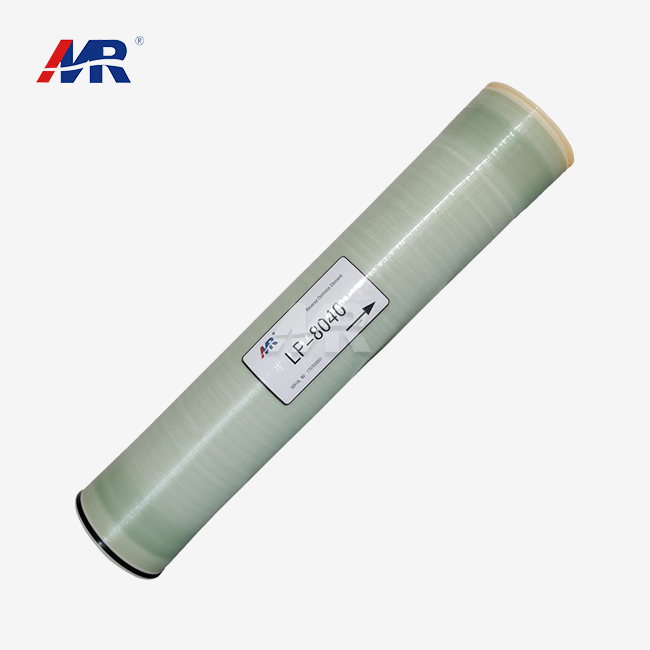

Are you looking for a tailored water purification solution for your industry? At Guangdong Morui Environmental Technology Co., Ltd, we specialize in cutting-edge water treatment technologies, including state-of-the-art reverse osmosis systems. Our expert team can help you navigate the complexities of water purification, offering customized solutions for industrial wastewater treatment, seawater desalination, and high-purity water production. With our extensive range of services, from equipment supply to installation and comprehensive after-sales support, we ensure your water treatment needs are met with precision and reliability. Experience the difference of our advanced RO membrane technology and benefit from our years of expertise in water purification. Contact us today at benson@guangdongmorui.com to discover how we can optimize your water treatment processes and drive your business forward with efficient, high-quality water solutions.

References

1. Johnson, A. M., & Smith, B. K. (2022). Comparative Analysis of Reverse Osmosis and Traditional Filtration Methods in Industrial Water Treatment. Journal of Water Purification Technology, 15(3), 287-302.

2. Chen, X., & Wang, Y. (2021). Advancements in Reverse Osmosis Membrane Technology for Water Treatment. Progress in Polymer Science, 112, 101324.

3. Thompson, R. L., et al. (2023). Energy Efficiency in Water Purification: A Review of Reverse Osmosis vs. Conventional Filtration Systems. Desalination, 528, 115612.

4. García-Vaquero, N., et al. (2022). Membrane Fouling in Reverse Osmosis: Mechanisms, Mitigation, and Management. Chemical Engineering Journal, 430, 132441.

5. Lee, K. P., & Arnot, T. C. (2021). A Review of Reverse Osmosis Membrane Materials for Desalination—Development to Date and Future Potential. Journal of Membrane Science, 370(1-2), 1-22.

6. Zhang, R., et al. (2023). Comparative Life Cycle Assessment of Reverse Osmosis and Traditional Filtration Systems in Municipal Water Treatment. Environmental Science & Technology, 57(9), 4521-4530.

_1745823981883.webp)