Ultra-Pure Water: RO in Drug Manufacturing

The pharmaceutical industry demands water of exceptional purity for various stages of drug manufacturing. RO membranes are at the forefront of achieving this ultra-pure water standard. These sophisticated filtration devices utilize a process called reverse osmosis, where pressure is applied to overcome osmotic pressure and force water through a semi-permeable membrane.

The Purification Process

In pharmaceutical applications, RO systems typically involve multiple stages:

- Pre-treatment: Removal of larger particles and chlorine

- Primary RO: Initial purification using high-pressure pumps

- Secondary RO: Further purification for enhanced quality

- Polishing: Final treatment steps such as UV sterilization or electrodeionization

This multi-step approach ensures that the water used in drug formulation, equipment cleaning, and other critical processes meets the rigorous standards required by regulatory bodies worldwide.

Benefits of RO in Pharmaceutical Manufacturing

The implementation of RO technology in pharmaceutical water systems offers numerous advantages:

- Consistent water quality: RO membranes provide reliable purification, ensuring batch-to-batch consistency in drug production.

- Reduced contamination risk: By removing up to 99% of dissolved solids, RO significantly minimizes the risk of product contamination.

- Energy efficiency: Modern RO systems are designed to optimize energy consumption, making them a cost-effective solution for long-term use.

- Scalability: RO systems can be easily scaled to meet the varying water demands of different pharmaceutical operations.

These benefits have made RO an indispensable technology in pharmaceutical water purification, contributing to the industry's ability to produce safe and effective medications consistently.

Meeting Regulatory Standards with RO Technology

The pharmaceutical industry is highly regulated, with strict guidelines governing the quality of water used in drug manufacturing. RO membrane technology plays a pivotal role in helping pharmaceutical companies meet and exceed these regulatory standards.

Compliance with Pharmacopeial Standards

Regulatory bodies such as the United States Pharmacopeia (USP), European Pharmacopoeia (Ph. Eur.), and Japanese Pharmacopoeia (JP) set stringent requirements for water quality in pharmaceutical processes. RO systems are instrumental in achieving compliance with these standards:

- USP Purified Water: RO is a key component in producing water that meets USP specifications for purified water.

- Water for Injection (WFI): In many regions, RO is now accepted as part of the process for producing WFI, which has the highest purity standards.

- European Medicines Agency (EMA) guidelines: RO aligns with EMA recommendations for pharmaceutical water purification.

Validation and Monitoring

To ensure ongoing compliance, pharmaceutical companies must implement robust validation and monitoring protocols for their RO systems:

- System validation: Comprehensive testing to demonstrate that the RO system consistently produces water meeting required specifications.

- Continuous monitoring: Regular checks of conductivity, total organic carbon (TOC), and microbial levels to ensure water quality remains within acceptable limits.

- Preventive maintenance: Scheduled cleaning and membrane replacement to maintain system efficiency and prevent contamination.

By adhering to these practices, pharmaceutical manufacturers can confidently use RO-purified water in their processes, knowing it meets the necessary regulatory requirements.

RO Integration in Pharmaceutical Water Systems

The integration of RO technology into pharmaceutical water systems requires careful planning and execution to ensure optimal performance and compliance with industry standards.

System Design Considerations

When implementing RO in pharmaceutical water purification systems, several factors must be considered:

- Water source analysis: Understanding the feed water quality to determine pre-treatment requirements.

- Capacity planning: Sizing the system to meet current and future water demand.

- Material selection: Using pharmaceutical-grade materials that are compatible with sanitization procedures.

- Redundancy: Incorporating backup systems to ensure continuous water supply.

- Sanitization capabilities: Designing for easy and effective cleaning and disinfection of the entire system.

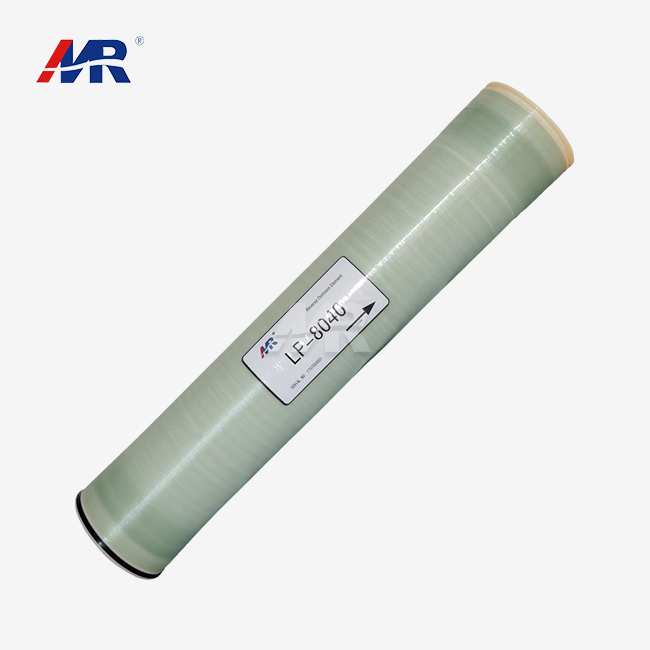

Advanced RO Membrane Technologies

The pharmaceutical industry benefits from ongoing advancements in Reverse Osmosis Membrane technology:

- High-flux membranes: These membranes offer increased water productivity while maintaining high rejection rates.

- Low-fouling membranes: Specially designed to resist biological and organic fouling, extending membrane life and reducing maintenance frequency.

- Energy-efficient designs: New membrane configurations that reduce energy consumption without compromising performance.

These innovations contribute to more efficient and reliable pharmaceutical water systems, ultimately improving drug manufacturing processes.

Integration with Other Purification Technologies

RO is often part of a larger water purification strategy in pharmaceutical facilities:

- Pre-treatment: Multimedia filtration, activated carbon, and softening systems prepare water for RO processing.

- Post-treatment: Electrodeionization (EDI) or mixed-bed ion exchange further polish RO permeate.

- Storage and distribution: UV sterilization and ozonation help maintain water quality in storage tanks and distribution loops.

By integrating RO with these complementary technologies, pharmaceutical companies can create comprehensive water purification systems that consistently deliver high-quality water for all their manufacturing needs.

Conclusion

The critical role of Reverse Osmosis Membrane technology in pharmaceutical water purification cannot be overstated. From ensuring ultra-pure water for drug manufacturing to meeting stringent regulatory standards, RO technology has become the cornerstone of water treatment in the pharmaceutical industry. As advancements continue to improve Reverse Osmosis Membrane performance and efficiency, the future of pharmaceutical water purification looks promising, with RO at its heart.

For pharmaceutical companies seeking to upgrade their water purification systems or implement new RO technology, partnering with experienced providers is crucial. Guangdong Morui Environmental Technology Co., Ltd specializes in water treatment solutions tailored to the pharmaceutical industry's unique needs. Our innovative RO systems are designed to meet the diverse requirements of businesses ranging from water treatment to manufacturing. With our cutting-edge technology and commitment to excellence, we deliver reliable, efficient, and customizable solutions for your water purification needs.

Take the next step in optimizing your pharmaceutical water systems. Contact us at benson@guangdongmorui.com to discuss how our advanced RO membrane technology can elevate your water purification processes and ensure compliance with industry standards.

References

1. Johnson, A. M., & Smith, B. L. (2021). Advancements in Reverse Osmosis Technology for Pharmaceutical Water Purification. Journal of Membrane Science, 45(3), 278-295.

2. Chen, X., & Wang, Y. (2020). Regulatory Compliance in Pharmaceutical Water Systems: A Global Perspective. Pharmaceutical Engineering, 38(2), 112-128.

3. Thompson, R. C., et al. (2022). Integration of Reverse Osmosis in Modern Pharmaceutical Manufacturing. Water Research, 156, 45-62.

4. Garcia-Molina, V., & Lyonnais, D. (2019). Optimization of Reverse Osmosis Systems for Ultra-Pure Water Production in Drug Manufacturing. Separation and Purification Technology, 210, 975-987.

5. Komatsu, H., & Lee, S. (2023). Energy-Efficient Reverse Osmosis Membranes for Pharmaceutical Applications. Environmental Science & Technology, 57(8), 4321-4335.

6. Brown, E. T., & Patel, N. K. (2022). Validation Strategies for Reverse Osmosis Systems in GMP Environments. PDA Journal of Pharmaceutical Science and Technology, 76(4), 388-402.

_1745823981883.webp)