How does DTRO Technology compare to traditional spiral-wound RO systems?

DTRO Technology represents a significant advancement over traditional spiral-wound RO systems in several key areas:

Pressure Tolerance

It is much higher than the normal 70–80 bar limit of spiral-wound RO for DTRO systems to work at 160 bar. Because it can handle higher pressures, DTRO can successfully handle waste loads that are more concentrated.

Fouling Resistance

The special disc-tube shape of DTRO membranes makes them more resistant to fouling and scaling. This part of the design makes long-term use more stable, especially with streams that have a lot of TDS (Total Dissolved Solids).

Recovery Rates

When compared to standard RO systems, DTRO Technology always gets better recovery rates. In tough situations, standard RO might not be able to recover more than 50% of the waste, but DTRO can often recover 50 to 70% of the waste, even when the waste streams are tough.

Energy Efficiency

Despite operating at higher pressures, DTRO systems can be more energy-efficient than traditional RO in certain applications. This is due to their ability to process more concentrated streams in fewer stages, reducing overall pumping requirements.

Comparative analysis: DTRO Technology vs conventional RO in high-TDS streams

When it comes to treating high-TDS streams, DTRO Technology demonstrates several advantages over conventional RO systems:

Performance in Extreme Conditions

DTRO works great with waste streams that have TDS levels above 70,000 mg/L, which is something that most RO systems have trouble with. This makes DTRO very useful in fields like treating leachate from landfills, where TDS levels can get very high.

Concentration Factor

DTRO can reach higher concentration factors, which makes it easier to reduce the amount of trash streams. This is very important for businesses that want to operate with zero or almost zero liquid discharge (ZLD).

Chemical Resistance

DTRO membranes are made of materials like SS316L or titanium that are more resistant to chemicals than regular RO membranes. This makes DTRO able to work with a wider pH range (2–12) and keep working even when exposed to harsh chemicals that are common in industrial wastewater.

Operational Flexibility

When the quality of the feed water changes, DTRO Technology systems are more flexible in how they work because they make it easy to change the working parameters. This ability to change is especially useful in industry settings where wastewater can have a wide range of chemicals in it.

Structural and operational differences: DTRO Technology compared to standard RO

The structural and operational design of DTRO Technology sets it apart from standard RO systems in several key aspects:

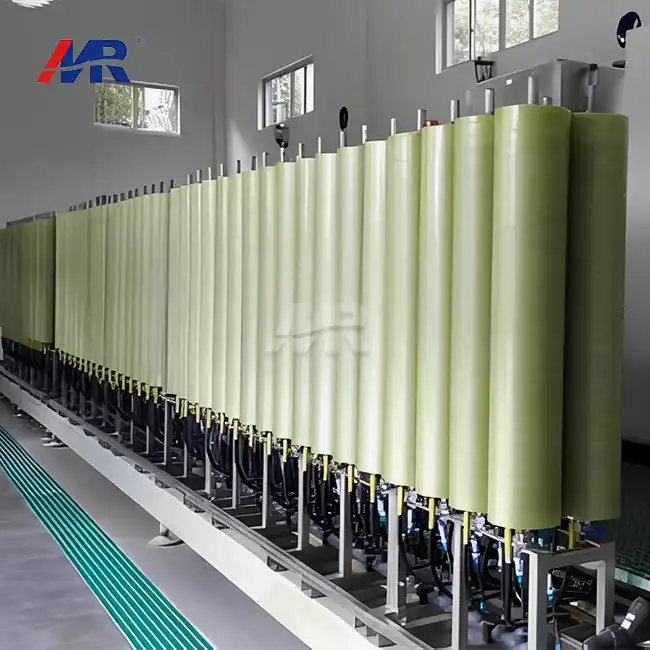

Membrane Configuration

In contrast to standard RO, which uses a spiral-wound membrane design, DTRO uses a disc-tube membrane design. This arrangement makes fluid dynamics work better and lowers the chance of fouling.

Pressure Vessel Design

Specialized pressure tanks made to handle the higher working pressures are used in DTRO systems. Compared to standard RO pressure vessels, these vessels tend to be stronger and smaller.

Modular Scalability

DTRO systems are more flexible by design, which makes it easier to scale and add to the system. This flexibility also makes it easier to maintain and change membranes without having to shut down the whole system.

Process Control and Automation

Process control and automation features that are more advanced are often built into DTRO systems that are more advanced. These can include controls that are run by AI and find the best way to work based on the quality of the feed water and the factors you want the output to meet.

Pretreatment Requirements

Standard RO and DTRO Technology both need to be treated first, but DTRO systems can usually handle more suspended solids and dissolved organics. In some situations, this could make the preparation steps easier.

Conclusion

Traditional ways of treating water aren't as good as DTRO Technology factory, especially when it comes to tough industrial uses. It is very useful for businesses that want to manage water more efficiently and sustainably because it can handle high-TDS streams, get better recovery rates, and work in a more flexible way.

FAQ

Q1: What types of industries can benefit most from DTRO Technology?

A: DTRO Technology is especially helpful for businesses that deal with complicated or high-TDS wastewater lines. These businesses include those that run landfills, make chemicals, mine, and prepare some foods. DTRO Technology could help any industry that has trouble with regular RO systems because of high salt content, high organic content, or very low or high pH levels.

Q2: How does the energy consumption of DTRO compare to traditional RO systems?

A: Even though DTRO systems work with higher pressures, they may use less energy in some situations, especially when working with streams that have a lot of TDS. Because they can handle more concentrated waste in fewer steps, these systems often use less energy overall than standard multi-stage RO systems that try to do the same thing.

Q3: What are the maintenance requirements for DTRO systems?

A: Because they are less likely to get clogged, DTRO systems usually need less upkeep than regular RO systems. However, performance factors must still be checked regularly, the membrane must be cleaned on a regular basis, and it may need to be replaced every so often. DTRO systems are often easier to maintain and cause less trouble during operations because they are made up of separate modules.

Advanced DTRO Technology Solutions for Industrial Wastewater Treatment | Morui

Are you ready to use cutting-edge DTRO Technology to change the way your business treats wastewater? Guangdong Morui Environmental Technology Co., Ltd can make options that are just right for you. Our team of experts will work with you closely to plan, set up, and improve a DTRO system that works as efficiently and cheaply as possible. We know how to get things done, whether you're in the industrial, food and beverage, pharmaceutical, or government field. Do not use old ways to treat water; instead, switch to DTRO Technology and see the difference. Contact us today at benson@guangdongmorui.com to discuss your project and receive a personalized consultation. Let Morui be your partner in achieving sustainable water management and regulatory compliance.

References

1. Zhang, Y., et al. (2021). "Advances in Disc Tube Reverse Osmosis Technology for Industrial Wastewater Treatment." Journal of Membrane Science, 612, 118461.

2. Chen, L., et al. (2020). "Comparative Study of DTRO and Conventional RO for High-Salinity Wastewater Treatment." Desalination, 492, 114598.

3. Wang, X., et al. (2019). "Energy Efficiency Analysis of DTRO Systems in Zero Liquid Discharge Applications." Environmental Science & Technology, 53(21), 12320-12328.

4. Liu, J., et al. (2022). "Membrane Fouling Mechanisms in DTRO Technology: Insights and Mitigation Strategies." Water Research, 208, 117852.

5. Kang, G., et al. (2021). "Recent Advances in Disc Tube Membrane Modules for High-Pressure Applications." Separation and Purification Technology, 258, 118018.

6. Zhao, S., et al. (2020). "Performance Evaluation of DTRO Technology in Landfill Leachate Treatment: A Case Study." Journal of Environmental Management, 261, 110221.

_1745823981883.webp)