Understanding Treatment Stages: Primary to Tertiary

The journey of wastewater through an industrial sewage treatment plant Free Sample involves several critical stages, each designed to progressively purify the water. Let's explore these stages in detail:

Primary Treatment: The First Line of Defense

Primary treatment serves as the initial step in the wastewater purification process. This stage primarily focuses on the physical separation of solid materials from the liquid waste stream. Key components of primary treatment include:

- Screening: Large debris and objects are removed using bar screens or rotating drum screens.

- Grit removal: Sand, gravel, and other heavy particles are separated through sedimentation or centrifugal force.

- Primary clarification: Suspended solids are allowed to settle, forming primary sludge.

The efficiency of primary treatment can significantly reduce the load on subsequent stages, improving overall plant performance.

Secondary Treatment: Biological Purification

Secondary treatment harnesses the power of microorganisms to break down dissolved organic matter. This biological process mimics nature's own purification mechanisms but in a controlled environment. Common methods include:

- Activated sludge process: Aerobic bacteria degrade organic pollutants in aeration tanks.

- Trickling filters: Wastewater is distributed over a bed of media covered with biofilm.

- Rotating biological contactors (RBCs): Partially submerged discs with bacterial growth rotate through wastewater.

Secondary treatment can remove up to 90% of organic matter and suspended solids, dramatically improving water quality.

Tertiary Treatment: Advanced Purification

Tertiary treatment, also known as advanced treatment, aims to remove remaining impurities and specific contaminants that secondary treatment cannot address effectively. This stage may include:

- Filtration: Sand filters or membrane systems remove fine particles.

- Nutrient removal: Processes to eliminate nitrogen and phosphorus compounds.

- Disinfection: UV light, chlorination, or ozonation to kill pathogens.

Tertiary treatment is crucial for producing high-quality effluent suitable for reuse or safe discharge into sensitive environments.

Emerging Technologies: What's New in Wastewater Treatment?

The field of industrial wastewater treatment is constantly evolving, with new technologies emerging to address increasingly complex challenges. Let's explore some of the innovative approaches revolutionizing the industry:

Advanced Oxidation Processes (AOPs)

AOPs utilize powerful oxidizing agents like ozone, hydrogen peroxide, and UV light to break down recalcitrant organic compounds. These processes are particularly effective for treating pharmaceutical and personal care product residues, which traditional methods struggle to remove.

Membrane Bioreactors (MBRs)

MBRs combine biological treatment with membrane filtration, offering several advantages:

- Smaller footprint compared to conventional activated sludge systems

- Higher quality effluent suitable for reuse applications

- Reduced sludge production

MBRs are increasingly popular in space-constrained industrial settings and for producing high-grade reclaimed water.

Electrochemical Treatment

Electrochemical processes use electricity to remove contaminants from wastewater. These methods are particularly effective for treating industrial effluents containing heavy metals, dyes, and other difficult-to-treat pollutants. Looking for a reliable industrial sewage treatment plant Free Sample? Advantages include:

- No need for additional chemicals

- Potential for resource recovery (e.g., metal reclamation)

- Compact design suitable for decentralized treatment

Anaerobic Ammonium Oxidation (Anammox)

Anammox is a biological process that converts ammonium directly to nitrogen gas, bypassing the traditional nitrification-denitrification pathway. This innovative approach offers:

- Lower energy consumption

- Reduced carbon footprint

- Smaller reactor volumes

Anammox is particularly useful for treating high-strength ammonia wastewater from industries such as food processing and chemical manufacturing.

Global Best Practices: Learning from Industry Leaders

Examining global best practices in industrial wastewater treatment provides valuable insights for improving efficiency, sustainability, and regulatory compliance. Let's explore some exemplary approaches from around the world:

Singapore's NEWater Initiative

Singapore's NEWater program is a shining example of water reclamation and reuse. The process involves:

- Microfiltration to remove particles and bacteria

- Reverse osmosis to remove dissolved contaminants

- UV disinfection as a final safety barrier

This multi-barrier approach produces ultra-clean water suitable for industrial use and indirect potable reuse, demonstrating the potential of advanced treatment technologies in water-scarce regions. Choosing a reliable industrial sewage treatment plant can help industries achieve these high standards of water quality and sustainability.

Germany's Zero Liquid Discharge (ZLD) Initiatives

Many German industries, particularly in the automotive and chemical sectors, have embraced ZLD systems. These advanced treatment trains aim to recover and reuse all wastewater, eliminating liquid discharge. Key components often include:

- Membrane processes (ultrafiltration, reverse osmosis)

- Evaporation and crystallization

- Solid waste management and resource recovery

ZLD systems not only minimize environmental impact but also recover valuable resources, aligning with circular economy principles.

Japan's Decentralized Treatment Approach

Japan's approach to wastewater management often involves decentralized treatment systems, particularly in urban areas. This strategy offers several advantages:

- Reduced need for extensive sewer networks

- Easier implementation of water reuse schemes

- Greater resilience to natural disasters

Many Japanese industries have adopted on-site treatment systems, often incorporating advanced technologies like MBRs, to meet stringent local regulations and conserve water resources.

Australia's Focus on Energy Efficiency

Australian wastewater treatment facilities, including those serving industries, have made significant strides in energy efficiency. Key strategies include:

- Biogas recovery from anaerobic digestion

- Implementation of energy-efficient aeration systems

- Use of renewable energy sources (solar, wind) to power treatment plants

These initiatives not only reduce operational costs but also minimize the carbon footprint of wastewater treatment processes.

Conclusion

As we've explored in this comprehensive guide, industrial sewage treatment and water purification are complex yet crucial processes for environmental protection and resource conservation. From understanding the fundamental stages of treatment to embracing emerging technologies and learning from global best practices, there's a wealth of knowledge to guide your wastewater management decisions. Partnering with a trusted industrial sewage treatment plant supplier ensures you have access to reliable solutions tailored to your specific needs.

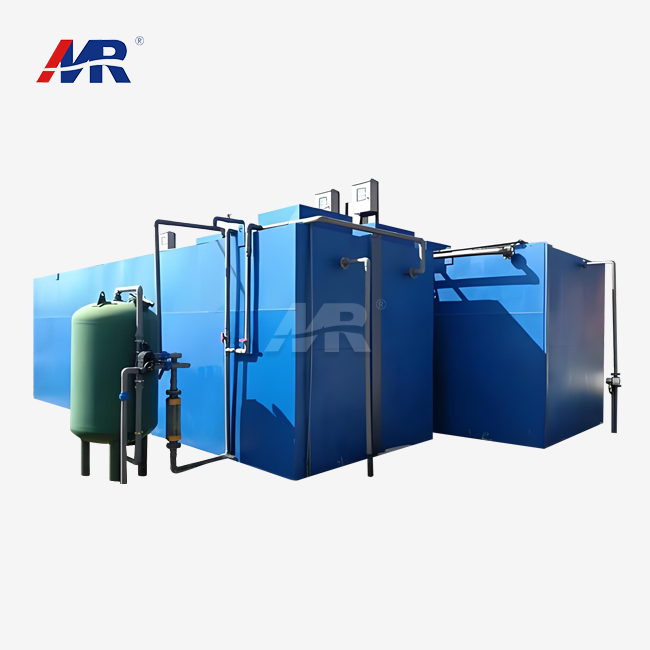

At Guangdong Morui Environmental Technology Co., Ltd, we're committed to helping industries across various sectors implement effective, efficient, and sustainable wastewater treatment solutions. Our state-of-the-art industrial sewage treatment plants are designed to tackle even the most challenging wastewater issues, ensuring compliance with regulatory standards while minimizing environmental impact.

Whether you're in the manufacturing, food and beverage, pharmaceutical, or municipal utility sector, we have the expertise and technology to meet your specific needs. Our modular designs allow for easy scalability, adapting to your changing requirements. With our own membrane production factory and partnerships with leading brands in water treatment equipment, we offer comprehensive solutions from equipment supply to installation, commissioning, and after-sales service.

Ready to take your industrial wastewater treatment to the next level? Contact us today at benson@guangdongmorui.com to discuss your needs and explore how our innovative solutions can benefit your business. Let's work together to protect our environment and conserve our precious water resources for future generations.

References

1. Smith, J. (2022). Advanced Industrial Wastewater Treatment Technologies: A Comprehensive Review. Environmental Engineering Science, 39(2), 112-128.

2. Johnson, A., & Brown, M. (2021). Global Trends in Industrial Water Management: Challenges and Opportunities. Water Research, 185, 116273.

3. Lee, S., et al. (2023). Emerging Contaminants in Industrial Effluents: Detection and Treatment Strategies. Journal of Hazardous Materials, 438, 129513.

4. García-Sánchez, M., & Martínez-Huitle, C. A. (2022). Electrochemical Treatment of Industrial Wastewater: Current Status and Future Perspectives. Chemical Engineering Journal, 430, 132765.

5. World Water Development Report 2023: Accelerating Change. UNESCO.

6. Tchobanoglous, G., Stensel, H. D., Tsuchihashi, R., & Burton, F. (2021). Wastewater Engineering: Treatment and Resource Recovery (6th ed.). McGraw Hill.

_1745823981883.webp)