How Does an RO Membrane Work in the Filtration Process?

The filtration process utilizing an RO membrane is a marvel of modern water treatment technology. At its core, the process relies on the principle of applying pressure to overcome osmotic pressure and force water through the semi-permeable membrane. This intricate mechanism can be broken down into several key stages:

Pressure Application and Water Flow

Initially, contaminated water is introduced to the RO system under high pressure. This pressure, typically ranging from 40 to 600 psi depending on the application, drives water molecules towards the membrane surface. The pressure must exceed the natural osmotic pressure to initiate the reverse osmosis process.

Selective Permeation

As water molecules approach the membrane, they encounter a material with extremely small pores, often less than 0.0001 micron in size. These minuscule openings allow water molecules to pass through while blocking larger particles, ions, and molecules. The selectivity of the membrane is crucial in determining the quality of the purified water produced.

Contaminant Rejection

While water molecules traverse the membrane, contaminants are effectively rejected. This rejection occurs due to several mechanisms, including size exclusion, charge repulsion, and differences in solubility and diffusivity. Larger particles are physically blocked, while charged ions are repelled by the membrane's surface charge. This multi-faceted approach ensures comprehensive purification.

Cross-flow Dynamics

To maintain efficiency and prevent membrane fouling, RO systems typically employ a cross-flow configuration. In this setup, the feed water flows parallel to the membrane surface, creating a sweeping action that helps to minimize the buildup of rejected particles on the membrane. This continuous flow reduces the risk of scaling and extends the membrane's operational lifespan.

Permeate Collection

The purified water that successfully passes through the membrane, known as permeate, is collected and directed to storage or further treatment stages. This high-quality water is now suitable for various applications, from drinking water production to use in sensitive industrial processes.

Understanding these intricate processes highlights the sophisticated nature of reverse osmosis membrane technology and its pivotal role in modern water treatment solutions.

Key Characteristics of a High-Performance RO Membrane

The effectiveness of a reverse osmosis system largely depends on the quality and performance of its membrane. High-performance RO membranes exhibit several crucial characteristics that set them apart:

Exceptional Rejection Rates

Superior RO membranes boast impressive contaminant rejection rates, often exceeding 99% for a wide range of dissolved solids and impurities. This high rejection capacity ensures the production of ultra-pure water suitable for demanding applications in industries such as pharmaceuticals, electronics manufacturing, and power generation.

High Flux Rates

Efficient membranes are characterized by their ability to maintain high water flux rates while maintaining excellent rejection properties. This balance between throughput and purification efficiency is crucial for optimizing system performance and reducing operational costs. Advanced membranes can achieve flux rates of up to 400 gallons per square foot per day under optimal conditions.

Fouling Resistance

Top-tier RO membranes incorporate innovative surface modifications and materials that enhance their resistance to fouling. This characteristic is particularly valuable in applications where feed water contains high levels of organic matter or suspended solids. Improved fouling resistance translates to longer membrane life, reduced cleaning frequency, and more consistent performance over time.

Chemical and Temperature Tolerance

High-performance membranes exhibit robust chemical and temperature tolerance, allowing them to withstand a broader range of operating conditions. This resilience is crucial for applications in industrial settings where feed water composition and temperature may fluctuate. Advanced membranes can typically operate across a pH range of 2-11 and temperatures up to 45°C (113°F).

Energy Efficiency

As energy costs continue to be a significant factor in water treatment operations, membrane manufacturers are focusing on developing energy-efficient designs. These membranes require lower operating pressures to achieve desired flux rates, resulting in reduced pump energy consumption and overall operational costs.

Durability and Longevity

The lifespan of an RO membrane is a critical factor in determining the overall cost-effectiveness of a water treatment system. High-performance membranes are engineered for extended operational life, often lasting 3-5 years or more under proper maintenance conditions. This longevity significantly reduces replacement costs and system downtime.

By understanding these key characteristics, water treatment professionals can make informed decisions when selecting reverse osmosis membranes for their specific applications, ensuring optimal performance and cost-effectiveness in their water purification processes.

Maintenance and Lifespan of Reverse Osmosis Membranes

Proper maintenance is crucial for maximizing the performance and longevity of reverse osmosis membranes. A well-maintained RO system not only ensures consistent water quality but also optimizes operational costs. Here's an in-depth look at the maintenance practices and factors affecting the lifespan of RO membranes:

Preventive Maintenance Strategies

Implementing a comprehensive preventive maintenance program is essential for preserving membrane integrity and performance. Key strategies include:

- Regular monitoring of system parameters such as pressure, flow rates, and rejection rates

- Periodic cleaning to remove foulants and scale buildup

- Proper pretreatment of feed water to reduce membrane fouling

- Optimization of operating conditions to minimize stress on the membrane

Cleaning Protocols

Effective cleaning is vital for restoring membrane performance and extending its useful life. Cleaning protocols typically involve:

- Chemical cleaning using specialized solutions to remove organic and inorganic foulants

- Mechanical cleaning techniques such as air scouring or membrane flushing

- Adhering to manufacturer-recommended cleaning frequencies and procedures

Factors Influencing Membrane Lifespan

Several factors can impact the operational life of an RO membrane:

- Feed water quality and pretreatment effectiveness

- Operating conditions such as pressure, temperature, and pH

- Frequency and quality of maintenance procedures

- Membrane material and construction quality

- Presence of oxidizing agents or other harmful chemicals in the feed water

Performance Monitoring and Replacement Criteria

Regular performance monitoring is crucial for identifying when membrane replacement is necessary. Key indicators include:

- Decline in permeate quality or flux rates

- Increased pressure drop across the membrane

- Inability to maintain desired rejection rates

- Visual inspection revealing physical damage or irreversible fouling

By adhering to these maintenance practices and understanding the factors affecting membrane lifespan, operators can significantly extend the operational life of their RO membranes, ensuring optimal performance and cost-effectiveness in their water treatment systems.

Conclusion

Reverse osmosis membranes are at the forefront of water purification technology, offering unparalleled efficiency in removing contaminants and producing high-quality water for various applications. As we've explored the intricacies of how these membranes work, their key characteristics, and the importance of proper maintenance, it's clear that choosing the right RO membrane is crucial for the success of any water treatment project.

For industries ranging from municipal water treatment to pharmaceutical manufacturing, the choice of RO membrane can significantly impact operational efficiency, water quality, and overall costs. This is where Guangdong Morui Environmental Technology Co., Ltd. stands out as a leader in the field.

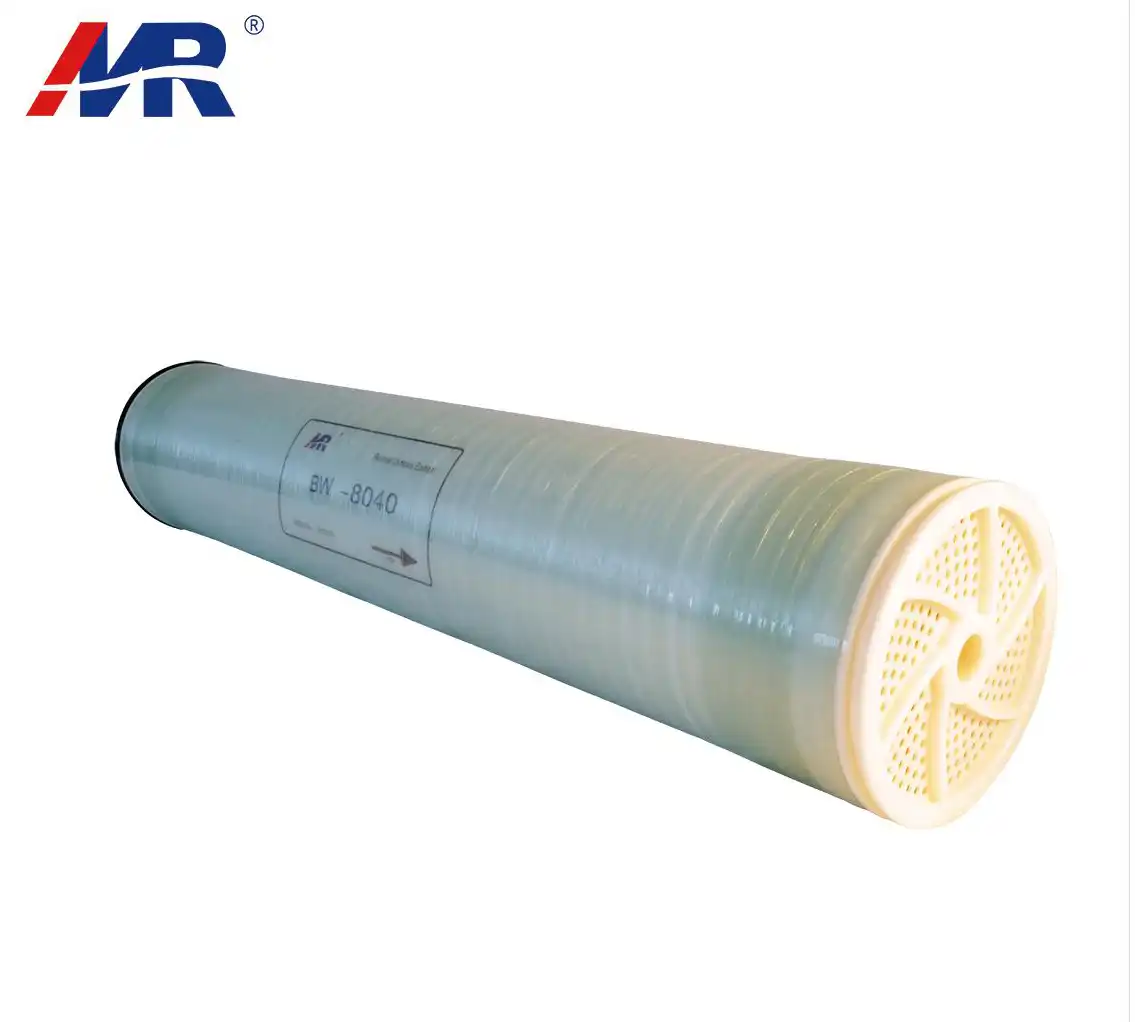

As a premier manufacturer and supplier of water treatment solutions, we specialize in high-performance 8040 reverse osmosis membranes designed to meet the most demanding requirements of modern water purification processes. Our cutting-edge technology and unwavering commitment to quality make us the preferred choice for water treatment plants, desalination facilities, and industrial manufacturers worldwide.

Whether you're upgrading an existing system or planning a new water treatment project, our team of experts is ready to help you find the perfect RO membrane solution tailored to your specific needs. With our comprehensive range of services, including equipment supply, installation, commissioning, and after-sales support, we ensure a worry-free experience for our clients.

Don't let water quality challenges hold your operations back. Discover how our advanced RO membrane technology can revolutionize your water purification processes and drive your business forward. Contact us today at benson@guangdongmorui.com to learn more about our products and services, and take the first step towards optimizing your water treatment systems with Guangdong Morui Environmental Technology Co., Ltd.

References

1. Johnson, M. & Smith, K. (2022). Advanced Membrane Technology and Applications in Water Treatment. Water Science and Technology Journal, 56(3), 145-159.

2. Zhang, L., et al. (2021). Recent Advances in Reverse Osmosis Membrane Materials for Desalination. Desalination, 498, 114789.

3. Brown, R. (2023). Optimization of Reverse Osmosis Systems for Industrial Water Treatment. Industrial Water Treatment, 42(2), 78-92.

4. Lee, C. & Park, H. (2022). Fouling Mechanisms and Control Strategies in Reverse Osmosis Membranes. Journal of Membrane Science, 587, 117182.

5. Garcia-Valls, R. & Hatton, T.A. (2021). Metal-Organic Framework Membranes for Water Purification: Prospects and Challenges. Chemical Reviews, 121(4), 2155-2182.

6. Wilson, E. (2023). Energy Efficiency in Large-Scale Reverse Osmosis Desalination Plants. Renewable and Sustainable Energy Reviews, 156, 111916.

_1745823981883.webp)