Core principles behind disc reverse osmosis technology

At the heart of DTRO innovation lies a progressive approach to film planning and liquid elements. Not at all like conventional spiral-wound RO membranes, DTRO modules utilize an arrangement of stacked disc-shaped films. This setup makes a turbulent stream design as water passes through the framework, which offers a few key advantages:

Enhanced Mass Transfer

The circular arrangement in DTRO systems is built to maximize turbulence inside the stream channels, advancing prevalent mass exchange compared to routine spiral-wound layers. This escalates turbulence, disturbs the boundary layer where solutes tend to gather, permitting water atoms to move more unreservedly through the film. As a result, the division of broken-up salts, natural matter, and other pollutants becomes more effective. This improved mass exchange not as it were boosts the penetration quality but also moves forward framework recuperation rates, empowering the treatment of challenging wastewater streams with higher consistency and execution stability.

Reduced Concentration Polarization

One of the most basic benefits of DTRO technology lies in its capacity to minimize concentration polarization, a major impediment in conventional RO systems. The disc-shaped layer structure and spacer plan make an exceedingly energetic stream administration that persistently disturbs solute collection close to the layer surface. This anticipates the arrangement of thick concentration layers that can decrease filtration productivity and increment osmotic pressure. By keeping up a uniform solute dissemination, DTRO modules maintain higher penetration flux and steady operation indeed beneath conditions of high salinity or natural stacking, making them perfect for leachate and mechanical wastewater treatment.

Self-Cleaning Mechanism

The self-cleaning nature of DTRO systems emerges straightforwardly from their interesting water-powered conditions. The high-velocity, twirling stream between the plates persistently evacuates potential foulants, scaling stores, and particulate matter from the film surface. This built-in cleaning impact minimizes fouling inclinations and extends layer life expectancy, altogether lessening the require for visit chemical cleanings. As a result, administrators benefit from lower support costs, longer operational uptime, and improved long-term execution of unwavering quality. This self-sustaining cleaning activity makes DTRO technology outstandingly well-suited for treating complex, variable wastewater streams where routine RO systems would quickly foul.

Unique advantages of DTRO over conventional membranes

DTRO systems offer several distinct advantages that set them apart from traditional reverse osmosis technologies:

Extreme Chemical Resistance

One of the characterizing qualities of DTRO systems lies in their uncommon chemical stability. The layers are developed from progressed polymeric materials planned to withstand extraordinary pH conditions extending from 0 to 14 without encountering auxiliary degradation or loss of execution. This wide chemical resilience makes DTRO systems perfect for treating exceedingly destructive mechanical effluents, such as those created in electroplating, mining, and chemical fabricating. Where routine RO membranes would rapidly break down, DTRO units proceed to work dependably, lessening layer substitution frequency and support costs while guaranteeing reliable treatment execution beneath cruel chemical environments.

High-Temperature Tolerance

DTRO modules are designed to keep up solidness and performance at hoisted temperatures, working successfully up to 50°C. This includes essentially growing their appropriateness to businesses that create hot wastewater streams, such as food and refreshment preparation, coloring, or pharmaceutical production. Not at all like routine layers that lose astuteness or endure from fast fouling beneath warm stretch, DTRO membranes keep up their porousness and selectivity. This capacity to handle hot nourish streams without requiring pre-cooling improves vitality efficiency and brings down overall operational costs. It also rearranges the framework plan by diminishing the requirement for temperature control hardware, progressing handle integration, and improving reliability.

Pressure Resilience

DTRO systems are able to withstand especially tall pressures—up to 120 bar—making them reasonable for a few of the most demanding water treatment applications. This strong weight resilience permits them to successfully handle profoundly concentrated brines, landfill leachate, and other complex squander streams that ordinary RO systems battle to treat. The strengthened module development and optimized layer bolster structure anticipate distortion or spillage beneath extraordinary working conditions. As a result, DTRO technology accomplishes higher recuperation rates and moves forward concentration capabilities, advertising a more proficient and solid arrangement for high-pressure filtration environments.

Compact Footprint

The compact and secluded plan of DTRO modules gives a noteworthy spatial advantage over conventional spiral-wound RO setups. Each circle module coordinates different film layers inside a vertical stack, maximizing surface zone utilization inside a small volume. This arrangement permits tall treatment capacity indeed in restricted spaces, making DTRO an amazing choice for retrofit ventures, containerized treatment units, or offices with strict space constraints. Also, the seclusion rearranges establishment, development, and support, empowering administrators to scale capacity or supplant components without disturbing the overall framework performance—a perfect highlight for cutting-edge, space-conscious mechanical operations.

Key industrial uses where DTRO excels

The unique capabilities of DTRO technology make it particularly well-suited for several challenging industrial applications:

Landfill Leachate Treatment

Landfill leachate presents a complex blend of natural and inorganic contaminants that can overpower ordinary treatment systems. DTRO modules, with their tall dismissal rates and fouling resistance, effectively remove these poisons while keeping up reliable execution over time.

Zero Liquid Discharge (ZLD) Systems

In businesses endeavoring for zero fluid release, DTRO modules play a pivotal part in concentrating squander streams to exceptionally high levels. Their capacity to handle raised weights and concentrated brines makes them perfect for the last stages of ZLD processes.

Pharmaceutical Wastewater Treatment

The pharmaceutical industry produces wastewater streams with complex natural compounds and possibly high concentrations of dynamic pharmaceutical ingredients (APIs). DTRO systems exceed expectations in evacuating these challenging contaminants, making a difference for producers to meet strict environmental regulations.

Mining and Metal Processing

DTRO modules are well-suited for treating corrosive mine seepage and metal-laden wastewaters. Their chemical resistance and tall dismissal rates empower the recovery of important metals while creating high-quality water for reuse or secure discharge.

Food and Beverage Production

In nourishment and refreshment manufacturing, DTRO technology offers points of interest in concentrate treatment and item recovery. The capacity to handle high-temperature streams and accomplish tall recuperation rates makes DTRO an alluring choice for moving forward handle productivity and reducing water consumption.

Conclusion

As businesses around the world confront expanding pressure to minimize their environmental impact and optimize asset utilization, DTRO modules manufacturer technology rises as an effective apparatus in the water treatment arms stockpile. It's an interesting combination of execution, strength, and flexibility that positions DTRO modules as a key arrangement for tending to the most challenging wastewater treatment scenarios.

FAQ

Q1: How does DTRO technology compare to traditional reverse osmosis in terms of energy efficiency?

A: DTRO technology generally offers improved energy efficiency compared to traditional reverse osmosis systems. The turbulent flow created by the disc configuration enhances mass transfer and reduces concentration polarization, allowing DTRO modules to operate at lower pressures while maintaining high rejection rates. This can lead to significant energy savings, especially when treating high-fouling or high-salinity streams.

Q2: What types of pretreatment are typically required for DTRO systems?

A: While DTRO systems are more resistant to fouling than conventional RO membranes, proper pretreatment is still essential for optimal performance and longevity. Common pretreatment steps may include multimedia filtration, activated carbon filtration, and chemical dosing for pH adjustment or scale inhibition. The specific pretreatment requirements will depend on the characteristics of the feed water and the intended application.

Q3: Can DTRO modules be used in seawater desalination applications?

A: Yes, DTRO modules can be effectively used in seawater desalination applications, particularly in small to medium-scale systems or in challenging environments. Their high-pressure tolerance and fouling resistance make them well-suited for handling the high salinity and potential organic content of seawater. However, the choice between DTRO and traditional RO membranes for large-scale desalination projects will depend on factors such as energy consumption, capital costs, and specific project requirements.

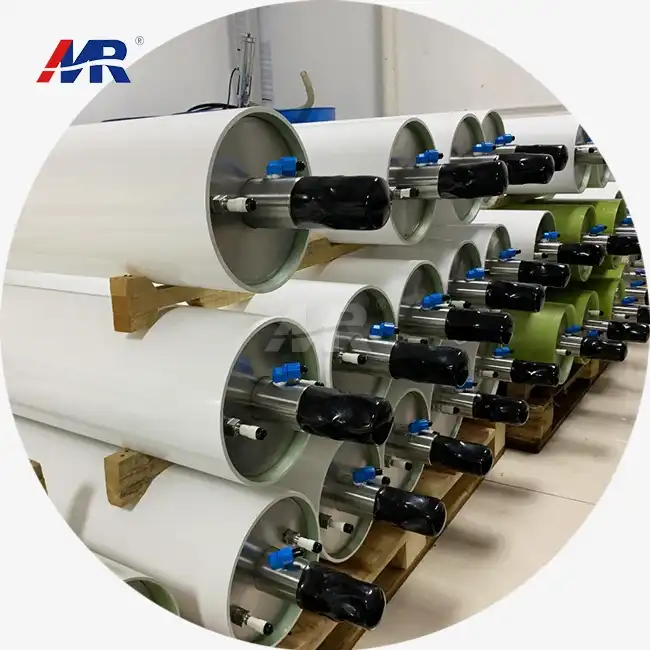

High-Performance DTRO Modules for Industrial Wastewater Treatment | Morui

Ready to revolutionize your industrial wastewater treatment process with cutting-edge DTRO technology? Guangdong Morui Environmental Technology Co., Ltd offers state-of-the-art DTRO modules designed to tackle your toughest water treatment challenges. Our experienced team provides comprehensive support, from system design to installation and ongoing maintenance, ensuring optimal performance and compliance with environmental regulations.

Don't let complex wastewater streams hinder your operations. Contact us today at benson@guangdongmorui.com to discuss how our DTRO solutions can help you achieve your water treatment goals efficiently and cost-effectively. With Morui's expertise and innovative technology, you'll be well-equipped to meet the demands of modern industrial water management.

References

1. Zhang, Y., et al. (2021). "Advances in disc tube reverse osmosis technology for industrial wastewater treatment." Journal of Water Process Engineering, 40, 101890.

2. Li, X., et al. (2020). "Performance comparison of disc tube reverse osmosis and spiral wound reverse osmosis in landfill leachate treatment." Separation and Purification Technology, 250, 117250.

3. Wang, J., et al. (2019). "Application of disc tube reverse osmosis technology in zero liquid discharge systems." Desalination, 465, 1-8.

4. Chen, G., et al. (2018). "Disc tube reverse osmosis membrane for high-salinity wastewater treatment: Performance and fouling behavior." Journal of Membrane Science, 549, 454-464.

5. Shu, L., et al. (2022). "Recent developments in disc tube reverse osmosis technology for pharmaceutical wastewater treatment." Chemical Engineering Journal, 428, 131112.

6. Zhao, S., et al. (2020). "Disc tube reverse osmosis for resource recovery from mining wastewater: A review." Journal of Cleaner Production, 257, 120394.

_1745823981883.webp)