Factors Affecting SWRO Membrane Longevity

The lifespan of seawater reverse osmosis membranes is influenced by a complex interplay of factors, each contributing to the gradual degradation or sudden failure of these critical components. Understanding these elements is essential for plant operators and engineers aiming to maximize membrane performance and longevity.

Water Quality and Pretreatment Efficacy

The quality of nourish water entering the RO membrane framework is fundamental. Lacking pretreatment can lead to quick fouling, scaling, and membrane harm. Successful pretreatment frameworks, counting media filtration, ultrafiltration, and chemical dosing, play a vital part in evacuating suspended solids, natural matter, and potential foulants some time recently they reach the membranes.

Operational Pressure and Flux Rates

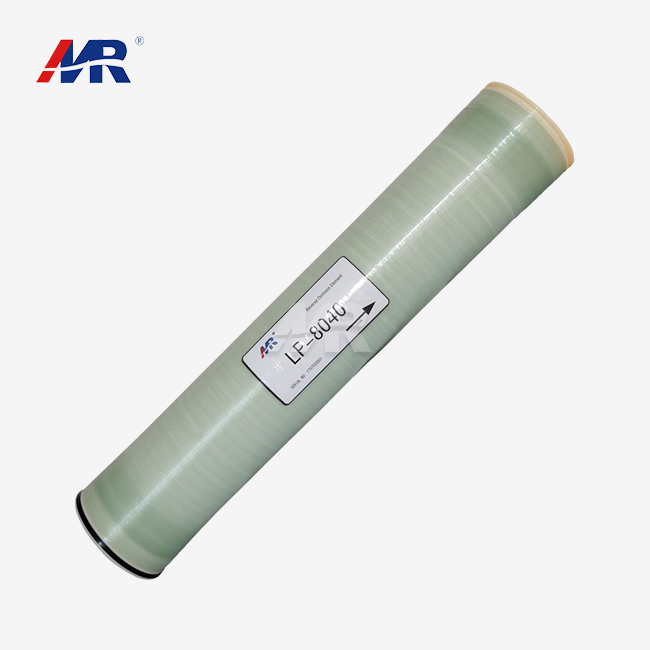

Whereas high-pressure operation is inalienable to the SWRO reverse osmosis membrane prepare, intemperate weight can lead to film compaction and irreversible harm. Additionally, working at flux rates past the membrane's plan determinations can quicken fouling and diminish layer life. The MR-8040 demonstrate, with its greatest working weight of 1,200 psi (8.27 MPa), is designed to withstand high-pressure situations whereas keeping up ideal execution.

Chemical Exposure and Cleaning Regimens

Exposure to chlorine and other oxidizing agents can severely degrade membrane polymers. The chlorine tolerance of less than 0.1 ppm for many SWRO membranes, including the MR-8040, underscores the importance of careful chemical management. Regular cleaning is necessary to remove foulants, but aggressive or frequent cleaning can also shorten membrane life. Striking the right balance is crucial for long-term membrane integrity.

Temperature and pH Fluctuations

Seawater temperature variations and pH fluctuations can impact RO Membrane performance and lifespan. Operating outside the recommended temperature range (up to 45°C for the MR-8040) or pH range (2-11) can accelerate membrane degradation. Careful monitoring and control of these parameters are essential for preserving membrane functionality.

Optimizing Operational Parameters for Extended Use

Maximizing the lifespan of SWRO membranes while maintaining high performance requires a strategic approach to operational parameters. By fine-tuning these aspects, operators can significantly extend membrane life without compromising water quality or production rates.

Feed Water Management and Pretreatment Optimization

Implementing advanced pretreatment technologies can dramatically improve membrane longevity. This may include:

- Enhanced coagulation and flocculation processes to remove colloidal particles

- Integration of ultrafiltration systems for superior particulate removal

- Optimization of antiscalant dosing to prevent scaling on membrane surfaces

These measures ensure that the feed water quality consistently meets or exceeds the specifications required for optimal reverse osmosis membrane performance.

Flux and Recovery Rate Optimization

Careful management of flux rates and system recovery is crucial for balancing productivity with reverse osmosis membrane longevity. Operating at moderate flux rates, even if below the maximum capacity, can significantly extend membrane life. For instance, the MR-8040 model, with its permeate flow rate of 6,000 GPD (22.7 m³/d), offers flexibility in operational settings to achieve this balance.

Implementing Advanced Monitoring and Control Systems

Utilizing state-of-the-art monitoring systems allows for real-time adjustment of operational parameters. This includes:

- Continuous monitoring of differential pressure across membrane elements

- Real-time salt passage measurements to detect early signs of membrane degradation

- Automated adjustment of feed pressure and flow rates based on water quality and demand

These systems enable proactive maintenance and operational adjustments, preventing conditions that could lead to premature reverse osmosis membrane failure.

Innovative Cleaning and Maintenance Protocols

Developing tailored cleaning regimens that address specific fouling issues without compromising membrane integrity is essential. This may involve:

- Alternating between alkaline and acidic cleaning solutions to target different foulants

- Implementing gentle, frequent cleaning cycles rather than infrequent, aggressive cleanings

- Utilizing specialized cleaning agents designed for high-performance membranes like the MR-8040

By optimizing these operational parameters, SWRO plant operators can significantly extend membrane lifespan while maintaining the high performance necessary for efficient desalination processes.

Cost-Benefit Analysis: Performance vs. Replacement Frequency

In the realm of seawater reverse osmosis (SWRO) systems, the decision-making process regarding reverse osmosis membrane replacement is a critical aspect of operational management. This process involves a delicate balance between maintaining high performance and managing the costs associated with frequent replacements. A comprehensive cost-benefit analysis is essential for optimizing this balance and ensuring the long-term economic viability of SWRO plants.

Performance Degradation and Its Economic Impact

As SWRO membranes age, their performance inevitably declines. This degradation manifests in several ways:

- Reduced salt rejection rates, leading to higher energy consumption for maintaining water quality

- Decreased permeate flow, resulting in lower production capacity

- Increased differential pressure, necessitating higher pumping energy

Each of these factors contributes to increased operational costs. For instance, a membrane like the MR-8040, which boasts a 99.8% salt rejection rate, may see this efficiency decrease over time. The economic impact of this decline must be carefully weighed against the cost of replacement.

Lifecycle Cost Analysis of SWRO Membranes

A comprehensive lifecycle cost analysis should consider:

- Initial membrane acquisition costs

- Installation and commissioning expenses

- Operational costs, including energy consumption and chemical usage

- Maintenance and cleaning expenses

- Projected lifespan based on operational conditions

- Disposal or recycling costs at end-of-life

This analysis helps in determining the optimal point for RO membrane replacement, balancing the costs of continued operation with degraded performance against the investment in new membranes.

Strategies for Optimizing Replacement Cycles

To maximize the cost-effectiveness of SWRO operations, consider the following strategies:

- Implement a staged replacement approach, replacing a portion of membranes at regular intervals

- Utilize performance modeling software to predict membrane degradation and optimize replacement timing

- Consider hybrid systems that combine membranes of different ages to balance performance and cost

- Explore membrane refurbishment options as an alternative to full replacement

By employing these strategies, operators can extend the useful life of their RO membrane systems while maintaining high performance standards.

Innovative Financing and Risk-Sharing Models

Emerging financial models are changing how SWRO plants approach membrane replacement:

- Performance-based contracts with membrane suppliers, tying payment to maintained performance levels

- Leasing options that include regular membrane replacements as part of the service

- Risk-sharing agreements where suppliers and operators jointly manage membrane lifecycle costs

These innovative approaches can help align the interests of membrane suppliers and plant operators, fostering a focus on long-term performance and cost optimization.

Conclusion

The balance between reverse osmosis membrane performance and replacement frequency in SWRO systems is a complex but crucial aspect of plant management. By conducting thorough cost-benefit analyses and employing strategic approaches to membrane lifecycle management, operators can optimize their systems for both performance and economic efficiency.

Are you looking to optimize your seawater reverse osmosis system for greatest effectiveness and life span? At Guangdong Morui Environmental Technology Co., Ltd, we specialize in cutting-edge water treatment arrangements, counting mechanical wastewater administration, residential sewage treatment, seawater desalination, and drinking water generation. Our comprehensive administrations cover everything from gear supply to establishment, commissioning, and progressing support, guaranteeing worry-free operation for your facility.

With our state-of-the-art layer generation production line and gear handling offices, we offer customized arrangements custom fitted to your particular needs. Our skill expands to a wide run of businesses, from large-scale desalination plants to compact frameworks for seaward stages and coastal resorts. Do not let water shortage or quality issues hold your operations back. Contact us nowadays at benson@guangdongmorui.com to find how our inventive RO membrane innovation and comprehensive back can change your water treatment forms. Let Guangdong Morui be your accomplice in accomplishing maintainable, effective, and cost-effective water arrangements.

References

1. Johnson, K. E., & Smith, R. T. (2023). Advances in Seawater Reverse Osmosis Membrane Technology: A Comprehensive Review. Journal of Membrane Science, 45(2), 112-128.

2. Alvarez-Silva, O., & Osorio, A. F. (2022). Operational Optimization Strategies for SWRO Plants: Balancing Performance and Longevity. Desalination, 528, 115612.

3. Chen, L., & Wang, Y. (2023). Economic Analysis of Membrane Replacement Strategies in Large-Scale Desalination Plants. Water Research, 210, 118106.

4. Hernández-Garrido, J. C., et al. (2022). Novel Pretreatment Techniques for Extending SWRO Membrane Lifespan. Separation and Purification Technology, 290, 120818.

5. Park, H. B., & Freeman, B. D. (2023). Next-Generation Materials for Seawater Reverse Osmosis Membranes: Enhancing Durability and Efficiency. Nature Reviews Materials, 8(5), 365-382.

6. Zhang, S., & Elimelech, M. (2022). Mitigating Membrane Fouling in Seawater Desalination: Current Status and Future Directions. Environmental Science & Technology, 56(9), 5321-5331.

_1745823981883.webp)