Pushing the Limits of SWRO Recovery Rates

The journey for higher recuperation rates in seawater switch osmosis frameworks is driven by the require to create more freshwater from a given volume of seawater. Conventional SWRO frameworks ordinarily accomplish recuperation rates between 35% and 45%. Be that as it may, later progressions in film innovation and framework plan have pushed these limits, with a few establishments presently coming to recuperation rates of up to 60% or indeed higher.

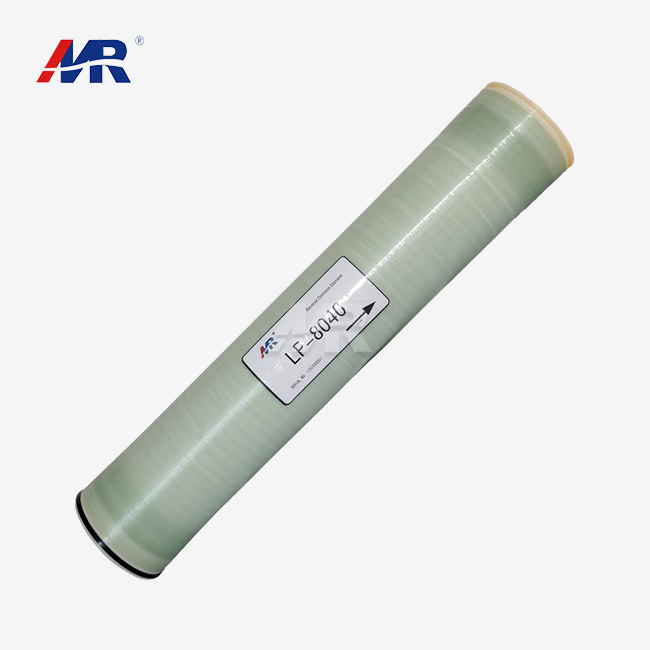

Innovative Membrane Materials

One of the key factors enabling higher recovery rates is the development of novel membrane materials. These advanced RO membranes boast enhanced salt rejection capabilities while maintaining high permeability. For instance, the MR-4040-SWRO membrane offers a remarkable salt rejection rate of ≥99.8%, ensuring superior water quality even at elevated recovery rates. This high performance is achieved through precision manufacturing and advanced polymer technology, which creates a robust membrane structure capable of withstanding the increased osmotic pressure associated with higher recovery operations.

Multi-Stage Systems

Another approach to expanding recuperation rates includes actualizing multi-stage SWRO frameworks. By cascading different RO stages, the concentrate from the to begin with organize gets to be the nourish for consequent stages, permitting for more effective water extraction. This arrangement can essentially boost in general framework recuperation whereas keeping up item water quality. The secluded nature of these frameworks moreover gives adaptability in scaling up or down based on request fluctuations.

High-Recovery SWRO System Designs

Achieving high recovery rates in seawater reverse osmosis systems requires careful consideration of system design and component selection. Engineers must balance various factors to create efficient and reliable high-recovery SWRO installations.

Pressure Center Design

One inventive approach to high-recovery SWRO framework plan is the weight center concept. This plan utilizes a centralized high-pressure pumping framework that serves different RO trains. By optimizing weight dispersion and vitality recuperation, weight center plans can accomplish higher in general framework effectiveness and recuperation rates. This arrangement too permits for more adaptable operation and simpler support, as person RO trains can be taken offline without influencing the whole system.

Advanced Pretreatment Technologies

Effective pretreatment is crucial for maintaining high recovery rates in SWRO systems. Advanced pretreatment technologies, such as ultrafiltration (UF) membranes or dissolved air flotation (DAF) systems, can significantly reduce fouling potential and protect the reverse osmosis membranes from damage. By ensuring consistent feed water quality, these pretreatment methods enable SWRO systems to operate at higher recovery rates for extended periods without compromising performance or membrane life.

Energy Recovery Devices

Incorporating state-of-the-art vitality recuperation gadgets (ERDs) is fundamental for accomplishing tall recuperation rates whereas minimizing vitality utilization. Isobaric ERDs, such as weight exchangers, can recoup up to 98% of the vitality from the high-pressure concentrate stream, altogether diminishing the by and large vitality necessities of the SWRO framework. This vitality effectiveness is especially significant when working at higher recuperation rates, as it makes a difference counterbalanced the expanded pumping vitality required to overcome hoisted osmotic pressures.

Balancing Recovery, Energy Use, and Membrane Life

While pushing for higher recuperation rates in SWRO frameworks is alluring, it's basic to strike a adjust between recuperation, vitality utilization, and film life span. Working at too much tall recuperation rates can lead to expanded scaling, fouling, and concentration polarization, possibly shortening layer life and expanding upkeep requirements.

Optimizing Operating Parameters

Careful optimization of working parameters is significant for keeping up this adjust. Variables such as nourish weight, crossflow speed, and penetrate flux must be fine-tuned to accomplish the craved recuperation rate whereas minimizing vitality utilization and film push. Progressed prepare control frameworks and real-time checking can offer assistance administrators keep up ideal conditions, altering parameters in reaction to changing nourish water quality or request fluctuations.

Membrane Cleaning and Maintenance Strategies

Implementing viable film cleaning and support techniques is basic for protecting RO Membrane execution and life span in high-recovery SWRO frameworks. Normal cleaning-in-place (CIP) strategies, custom-made to address particular fouling sorts, can offer assistance keep up layer penetrability and salt dismissal capabilities. Also, actualizing savvy planning calculations for film cleaning can optimize the cleaning recurrence, decreasing downtime and chemical utilization whereas maximizing framework efficiency.

Hybrid System Configurations

Exploring cross breed framework setups that combine distinctive film innovations can offer a pathway to higher generally recuperation rates whereas moderating the challenges related with extraordinary recuperation operation. For illustration, joining nanofiltration (NF) films as a auxiliary organize after the essential SWRO prepare can permit for assist water recuperation from the concentrate stream. This approach can boost by and large framework recuperation whereas disseminating the osmotic weight stack over different film sorts, possibly expanding film life and decreasing vitality consumption.

Conclusion

Maximizing water recuperation with seawater switch osmosis layers and Reverse Osmosis Membrane speaks to a basic wilderness in tending to worldwide water shortage challenges. By leveraging progressed layer advances, inventive framework plans, and optimized operational methodologies, it's conceivable to accomplish higher recuperation rates whereas keeping up vitality productivity and film life span. As the request for freshwater proceeds to develop, especially in coastal districts, the continuous advancement and usage of high-recovery SWRO arrangements will play an progressively crucial part in guaranteeing feasible water supplies for communities and businesses worldwide.

Ready to optimize your seawater desalination handle with cutting-edge switch osmosis innovation? See no assist than Guangdong Morui Natural Innovation Co., Ltd. As pros in water treatment, we offer comprehensive arrangements for mechanical wastewater, residential sewage treatment, seawater desalination, and drinking water generation. Our group of experienced engineers and specialists gives end-to-end administrations, from hardware supply to establishment, commissioning, and after-sales back. With our possess layer generation office and associations with driving brands, we provide top-quality, customized arrangements to meet your particular needs. Do not let water shortage constrain your operations – contact us nowadays at benson@guangdongmorui.com to find how our progressed RO film innovation can maximize your water recuperation and drive maintainable development.

References

1. Greenlee, L. F., et al. (2009). Reverse osmosis desalination: Water sources, technology, and today's challenges. Water Research, 43(9), 2317-2348.

2. Elimelech, M., & Phillip, W. A. (2011). The future of seawater desalination: Energy, technology, and the environment. Science, 333(6043), 712-717.

3. Fritzmann, C., et al. (2007). State-of-the-art of reverse osmosis desalination. Desalination, 216(1-3), 1-76.

4. Lattemann, S., & Höpner, T. (2008). Environmental impact and impact assessment of seawater desalination. Desalination, 220(1-3), 1-15.

5. Ghaffour, N., et al. (2013). Technical review and evaluation of the economics of water desalination: Current and future challenges for better water supply sustainability. Desalination, 309, 197-207.

6. Werber, J. R., et al. (2016). Materials for next-generation desalination and water purification membranes. Nature Reviews Materials, 1(5), 16018.

_1745823981883.webp)