High-pressure pumps in reverse osmosis plants: Function and types

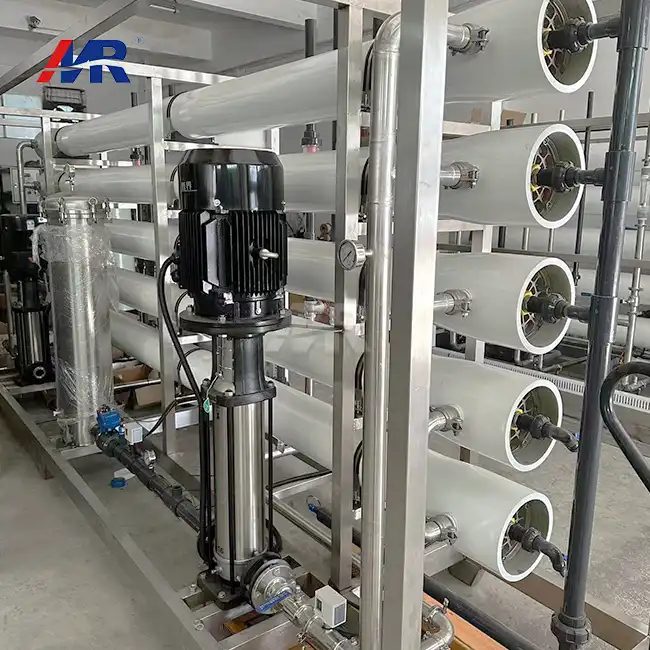

High-pressure pumps are the powerhouse of any reverse osmosis plant. Their primary function is to generate the necessary pressure to force water through the semi-permeable membranes, overcoming the natural osmotic pressure. This process is fundamental to the separation of pure water from contaminants.

Types of high-pressure pumps

Several types of high-pressure pumps are commonly used in industrial RO systems:

- Centrifugal pumps: These are widely used due to their reliability and efficiency in handling large water volumes.

- Positive displacement pumps: Ideal for smaller systems or those requiring precise flow control.

- Axial piston pumps: Known for their high efficiency and ability to handle varying flow rates.

The selection of the appropriate pump type depends on factors such as system capacity, required pressure, and energy efficiency considerations. For instance, a large-scale BWRO plant might utilize multiple high-capacity centrifugal pumps to achieve the desired flow rate and pressure.

Energy recovery devices

Modern reverse osmosis systems often incorporate energy recovery devices (ERDs) to enhance efficiency. These devices harness the energy from the high-pressure concentrate stream, reducing overall energy consumption. Popular ERD types include pressure exchangers and turbochargers, which can significantly lower operational costs in large-scale installations.

Importance of pressure vessels in industrial RO systems

Pressure vessels are critical components in industrial reverse osmosis systems, housing the membrane elements and withstanding the high pressures required for the filtration process. These cylindrical containers are designed to endure continuous operation under extreme pressure conditions while maintaining structural integrity.

Material considerations

The choice of materials for pressure vessels is paramount to ensure longevity and performance:

- Fiberglass reinforced plastic (FRP): Lightweight, corrosion-resistant, and suitable for most applications.

- Stainless steel: Offers superior strength and is preferred in high-pressure or high-temperature scenarios.

- Super duplex stainless steel: Utilized in seawater desalination plants due to its exceptional corrosion resistance.

The selection of pressure vessel material depends on factors such as operating pressure, water quality, and system lifespan requirements. For example, a BWRO plant treating brackish water might opt for FRP vessels, while a seawater desalination facility would likely choose super duplex stainless steel for its superior corrosion resistance.

Membrane arrangement

Pressure vessels accommodate multiple membrane elements in series, typically housing 6 to 8 elements per vessel. This arrangement maximizes the utilization of available space and optimizes the filtration process. The configuration of pressure vessels within the system affects overall performance and recovery rates.

Control panels and monitoring tools for BWRO plant efficiency

Advanced control panels and monitoring tools are essential for maintaining optimal performance and efficiency in brackish water reverse osmosis (BWRO) plants. These sophisticated systems provide real-time data and control capabilities, enabling operators to make informed decisions and ensure smooth operation.

Key features of modern control panels

State-of-the-art control panels in industrial RO systems typically include:

- Programmable Logic Controllers (PLCs): These devices automate system operations and manage complex processes.

- Human-Machine Interface (HMI): Touchscreen displays provide intuitive access to system parameters and controls.

- Remote monitoring capabilities: Allow operators to access and control the system from off-site locations.

- Data logging and trend analysis: Facilitate performance optimization and predictive maintenance.

These features enable precise control over critical parameters such as feed pressure, flow rates, and recovery ratios, ensuring optimal performance of the reverse osmosis system.

Monitoring tools and sensors

A comprehensive array of monitoring tools and sensors is crucial for maintaining BWRO plant efficiency:

- Pressure transducers: Monitor pressure at various points in the system.

- Flow meters: Measure feed, permeate, and concentrate flow rates.

- Conductivity sensors: Assess the quality of feed water and permeate.

- pH meters: Monitor and control pH levels to prevent membrane fouling.

- Temperature sensors: Ensure optimal operating conditions for membranes.

These instruments provide valuable data for performance analysis, troubleshooting, and optimization of the reverse osmosis process. For instance, sudden changes in permeate conductivity might indicate membrane damage or fouling, prompting timely maintenance actions.

In conclusion, the key components of industrial reverse osmosis equipment work in concert to deliver high-quality purified water. From high-pressure pumps that drive the filtration process to robust pressure vessels that house the membranes, and sophisticated control panels that ensure optimal performance, each element plays a vital role in the efficiency and effectiveness of the system.

Are you looking to implement or upgrade a reverse osmosis system for your industrial water treatment needs? Guangdong Morui Environmental Technology Co., Ltd. is your trusted partner in water purification solutions. With our expertise in industrial wastewater treatment, seawater desalination, and drinking water production, we offer cutting-edge reverse osmosis plants tailored to your specific requirements.

Our comprehensive services include equipment supply, installation, commissioning, and after-sales support. Leveraging our in-house membrane production capabilities and partnerships with leading brands, we deliver reliable, efficient, and customizable solutions for diverse industries. Whether you're in manufacturing, food and beverage, pharmaceuticals, or municipal utilities, our team of experienced engineers is ready to assist you in optimizing your water treatment processes.

Take the next step towards superior water quality and operational efficiency. Contact us today at benson@guangdongmorui.com to discuss how our advanced reverse osmosis systems can meet your industrial water purification needs.

References

1. Johnson, A. R., & Wilson, T. E. (2018). Advanced Reverse Osmosis Systems for Industrial Applications. Water Technology Journal, 42(3), 215-229.

2. Zhao, Y., & Lee, K. P. (2019). Energy Recovery Devices in Reverse Osmosis Desalination: A Comprehensive Review. Desalination and Water Treatment, 157, 162-180.

3. Smith, R. B., & Brown, C. D. (2020). Materials Selection for Pressure Vessels in Seawater Reverse Osmosis Plants. Corrosion Science and Technology, 55(4), 378-392.

4. Rodriguez, M. A., et al. (2021). Automation and Control Strategies for Large-Scale Reverse Osmosis Plants. Journal of Membrane Science, 618, 118632.

5. Chen, L., & Wang, Q. (2022). Membrane Fouling Prevention in Industrial Reverse Osmosis Systems: Current Practices and Future Directions. Separation and Purification Technology, 290, 120818.

6. Thompson, J., & Garcia-Segura, S. (2023). Sustainable Operation of Brackish Water Reverse Osmosis Plants: Challenges and Opportunities. Environmental Science: Water Research & Technology, 9(5), 1425-1442.

_1745823981883.webp)