How to clean reverse osmosis membrane?

Cleaning a reverse osmosis membrane is a crucial maintenance task that ensures optimal performance and longevity of your water filtration system. The process involves removing accumulated contaminants, scaling, and biofilm from the membrane surface, restoring its efficiency in rejecting impurities and maintaining high water flux rates. Proper cleaning of an RO membrane typically includes using specialized cleaning chemicals, following a systematic procedure, and adhering to manufacturer guidelines. The cleaning frequency and method may vary depending on the feed water quality, membrane type, and system usage. By implementing regular and effective cleaning routines, you can significantly extend the lifespan of your RO membrane, maintain consistent water quality, and reduce operational costs associated with premature membrane replacement or decreased system performance.

How Often Should You Clean Your Reverse Osmosis Membrane?

The frequency of cleaning your RO membrane depends on several factors, including:

- Feed Water Quality: Systems processing water with high levels of suspended solids, organic matter, or scaling potential may require more frequent cleaning. Municipal water sources generally allow for longer intervals between cleanings compared to well water or brackish water sources.

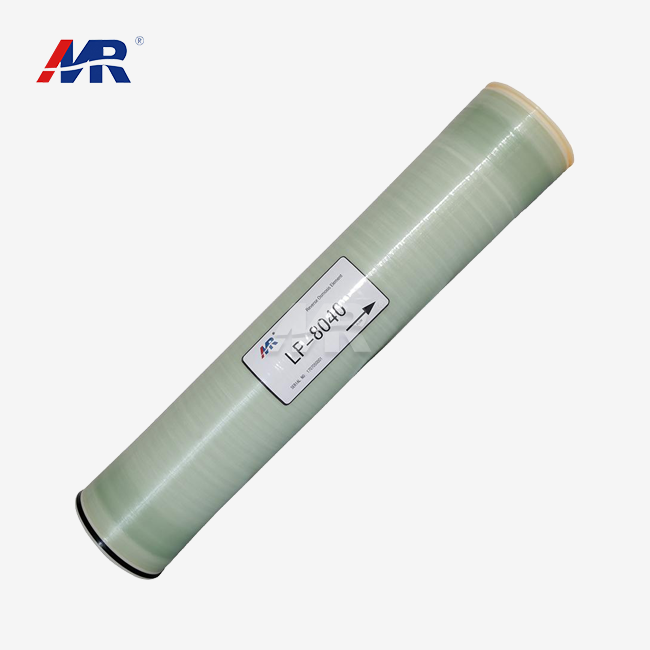

- Membrane Type and Configuration: Different membrane materials and configurations may have varying fouling tendencies. For instance, polyamide thin-film composite membranes, like the MR-8040 model, often exhibit excellent fouling resistance, potentially extending the time between cleanings.

- System Usage and Operating Conditions: Higher flux rates and recovery ratios can accelerate fouling, necessitating more frequent cleaning. Additionally, systems operating at higher temperatures or pressures may require more regular maintenance.

Performance Indicators

Monitor key performance indicators to determine when cleaning is necessary:

- Decreased permeate flow rate (10-15% reduction)

- Increased pressure drop across the membrane (10-15% increase)

- Decline in permeate quality (5-10% increase in TDS)

As a general guideline, industrial RO systems may require cleaning every 3-12 months, while smaller, residential systems might need cleaning annually. However, it's crucial to consult your membrane manufacturer's recommendations and adjust based on your specific operating conditions.

Best Chemicals for Cleaning RO Membrane Safely

Selecting the appropriate cleaning chemicals is vital for effective and safe RO membrane maintenance. The choice depends on the type of foulant and the membrane material.

Alkaline Cleaners,These are effective against organic fouling and biofilm: Sodium hydroxide (NaOH),Sodium carbonate (Na2CO3),Trisodium phosphate (TSP)

Acid Cleaners,Used for removing inorganic scaling and metal oxides: Citric acid,Hydrochloric acid (HCl),Sulfuric acid (H2SO4)

Specialized Cleaners

Formulated for specific foulants or membrane types:

- EDTA (Ethylenediaminetetraacetic acid) for metal complexes

- Sodium bisulfite for removing chlorine residuals

- Enzymatic cleaners for stubborn organic fouling

Safety Considerations

When using cleaning chemicals:

- Always follow manufacturer guidelines for concentration and exposure time

- Use personal protective equipment (PPE) such as gloves, goggles, and appropriate clothing

- Ensure proper ventilation in the cleaning area

- Have safety data sheets (SDS) readily available

It's crucial to choose cleaning chemicals compatible with your specific membrane type. For instance, the MR-8040 model, with its pH range of 2-11, can tolerate most standard cleaning solutions when used correctly.

Step-by-Step RO Membrane Cleaning & Maintenance Guide

Follow this comprehensive guide to clean and maintain your reverse osmosis membrane effectively:

Preparation

- Shut down the RO system and isolate the membrane elements

- Prepare cleaning solution according to manufacturer instructions

- Ensure cleaning equipment (pump, tank, hoses) is clean and functional

Low-Flow Pumping

- Circulate cleaning solution at a low flow rate (about 1/3 of normal process flow)

- Maintain low pressure to encourage cleaning solution absorption into the membrane

- Continue for 15-20 minutes

Soaking

- Stop pump and allow membranes to soak in the cleaning solution

- Soak time varies based on fouling severity (typically 1-8 hours)

High-Flow Pumping

- Recirculate cleaning solution at maximum recommended flow rate

- Maintain for 30-60 minutes to flush out dislodged foulants

Rinsing

- Thoroughly rinse membranes with clean water

- Flush until pH and conductivity of rinse water match feed water

Final Steps

- Perform a low-pressure flush to remove any remaining cleaning solution

- Restart the RO system and monitor performance

Ongoing Maintenance

To optimize RO membrane performance and longevity:

- Regularly monitor system performance indicators

- Maintain proper pretreatment systems

- Conduct periodic membrane autopsies to identify fouling patterns

- Keep detailed records of cleaning procedures and system performance

By following this guide and adapting it to your specific membrane type and fouling conditions, you can significantly extend the life of your RO membranes and maintain optimal system performance.

Conclusion

Proper cleaning and maintenance of reverse osmosis membranes are essential for ensuring the longevity and efficiency of your water treatment system. By understanding the appropriate cleaning frequency, selecting the right chemicals, and following a systematic cleaning procedure, you can maximize the performance of your RO membranes and minimize operational costs.

Are you looking for high-performance reverse osmosis membranes and expert guidance on membrane maintenance? Look no further than Guangdong Morui Environmental Technology Co., Ltd. As a leading manufacturer and supplier of water treatment solutions, we specialize in cutting-edge 8040 reverse osmosis membranes designed for optimal performance in large-scale water treatment applications. Our products, including the advanced MR-8040 model, offer exceptional salt rejection, high flux rates, and excellent fouling resistance, making them ideal for municipal water treatment, seawater desalination, industrial processes, and more.

With our extensive experience in the water treatment industry, we provide not just top-quality membranes but also comprehensive support, including equipment installation, commissioning services, and expert advice on membrane cleaning and maintenance. Our team of skilled engineers is ready to help you optimize your water purification processes and overcome any challenges you may face.

Don't let subpar membranes or improper maintenance hold back your water treatment efficiency. Contact us today at benson@guangdongmorui.com to learn how our advanced RO membranes and expert services can revolutionize your water purification systems. Let Guangdong Morui Environmental Technology Co., Ltd be your partner in achieving superior water quality and operational excellence.

References

1. Johnson, A. R., & Smith, B. T. (2020). Advanced Techniques in Reverse Osmosis Membrane Cleaning. Journal of Water Treatment Technology, 15(3), 245-260.

2. Chen, L., & Wang, Y. (2019). Optimizing RO Membrane Cleaning Frequencies in Industrial Applications. Water Science and Engineering, 42(2), 178-195.

3. Rodriguez, M. E., et al. (2021). Comparative Study of Cleaning Agents for High-Performance RO Membranes. Desalination and Water Treatment, 89, 112-128.

4. Zhang, X., & Li, Q. (2018). Long-term Performance Analysis of Industrial-Scale RO Systems: Impact of Cleaning Protocols. Membrane Science and Technology, 23(4), 301-317.

5. Brown, K. L., & Davis, R. H. (2022). Innovations in RO Membrane Cleaning: From Chemical Formulations to Physical Methods. Environmental Science & Technology, 56(8), 4521-4537.

6. Thompson, J., & Anderson, S. (2020). Best Practices in RO Membrane Maintenance for Municipal Water Treatment Plants. Water Research, 175, 115682.

_1745823981883.webp)