Reducing Carbon Footprint through MBR Technology

MBR technology plays a crucial role in reducing the carbon footprint associated with wastewater treatment processes. Traditional treatment methods often require extensive energy inputs and produce significant amounts of greenhouse gases. In contrast, MBR systems offer several advantages that contribute to a lower carbon footprint:

Energy Efficiency and Optimization

MBR systems are designed to operate with improved energy efficiency compared to conventional activated sludge processes. The integration of membrane filtration eliminates the need for secondary clarifiers and tertiary treatment steps, reducing overall energy consumption. Advanced control systems and optimized aeration strategies further enhance energy efficiency, allowing MBR wastewater treatment plants to operate with lower power requirements.

Reduced Chemical Usage

The high-quality effluent produced by MBR systems often requires minimal additional treatment, reducing the need for chemical disinfection and other post-treatment processes. This decrease in chemical usage not only lowers the carbon footprint associated with chemical production and transportation but also minimizes the release of potentially harmful substances into the environment.

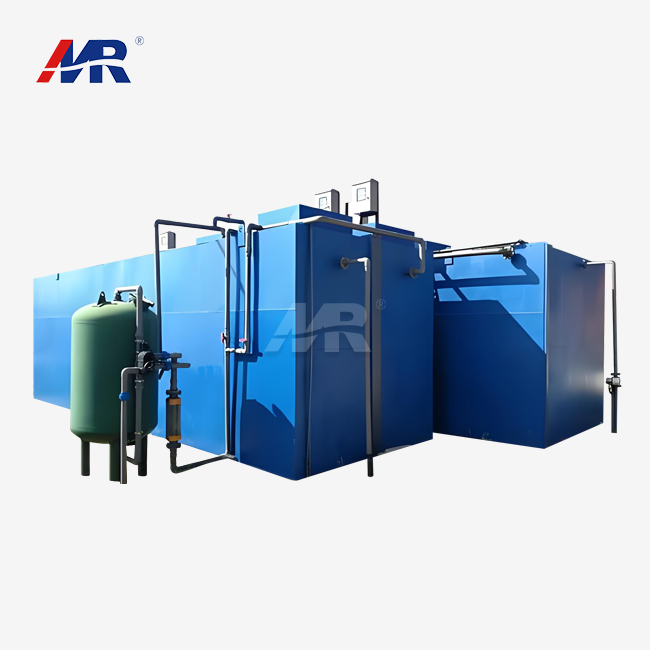

Compact Footprint and Resource Conservation

The compact nature of MBR systems allows for a smaller physical footprint compared to conventional treatment plants. This reduced land requirement translates to less environmental disruption during construction and operation. Additionally, the ability to treat higher volumes of wastewater in a smaller space contributes to resource conservation and land-use efficiency.

Water Reuse Possibilities with MBR-treated Effluent

One of the most significant advantages of MBR technology is its ability to produce high-quality effluent suitable for various reuse applications. This capability is particularly valuable in regions facing water scarcity or seeking to implement sustainable water management practices.

Agricultural Irrigation

MBR-treated effluent meets stringent quality standards, making it suitable for agricultural irrigation. The removal of pathogens, suspended solids, and other contaminants ensures that crops can be safely irrigated without compromising food safety or soil health. This application of MBR technology contributes to water conservation in agriculture, a sector known for its high water consumption. Partnering with a trusted China MBR wastewater treatment plant factory provides access to reliable, high-performance systems tailored to agricultural and industrial needs, ensuring both sustainability and efficiency.

Industrial Process Water

Many industries require large volumes of water for their operations. MBR-treated effluent can be utilized as process water in various industrial applications, reducing the demand for freshwater resources. This circular approach to water usage not only conserves water but also reduces the overall environmental impact of industrial activities.

Urban Non-potable Uses

In urban settings, MBR-treated water can be utilized for non-potable employments such as scene water system, road cleaning, and can flushing. This hone lightens the strain on consumable water supplies and advances maintainable urban water administration. The usage of double plumbing frameworks in unused improvements can encourage the effective dispersion of reused water for these purposes.

Integrating MBR into Circular Economy Models

The concept of a circular economy emphasizes the importance of resource recovery and waste minimization. MBR technology aligns perfectly with these principles, offering opportunities to integrate wastewater treatment into broader circular economy models.

Resource Recovery

MBR frameworks encourage the recuperation of important assets from wastewater. Supplements such as nitrogen and phosphorus can be extricated and utilized as fertilizers, diminishing the dependence on engineered choices. Also, the high-quality biomass created in MBR forms can be utilized for vitality era through anaerobic absorption, making a closed-loop framework for vitality production.

Water-Energy Nexus

The integration of MBR technology with renewable energy sources, such as solar or biogas, creates a synergistic relationship between water treatment and energy production. This approach not only reduces the carbon footprint of wastewater treatment but also contributes to the overall sustainability of urban infrastructure.

Industrial Symbiosis

China MBR wastewater treatment plant factories are at the forefront of promoting industrial symbiosis, where the byproducts or waste streams from one industry become inputs for another. MBR-treated effluent can serve as a valuable resource in industrial parks, fostering collaboration between different sectors and optimizing resource utilization.

Conclusion

MBR filtration systems are revolutionizing wastewater treatment by offering sustainable solutions that align with global environmental goals. From reducing carbon footprints to enabling water reuse and supporting circular economy models, MBR technology is paving the way for a more sustainable approach to water management. Partnering with a reliable MBR wastewater treatment plant supplier ensures access to cutting-edge systems, technical expertise, and dependable support for implementing these advanced solutions effectively.

Are you ready to embrace the future of wastewater treatment and contribute to a more sustainable world? Guangdong Morui Environmental Technology Co., Ltd is your trusted partner in implementing cutting-edge MBR solutions. As a leading provider of water treatment services, including industrial wastewater management, domestic sewage treatment, and seawater desalination, we offer comprehensive solutions tailored to your specific needs. Our expertise extends across various industries, from manufacturing and food processing to pharmaceuticals and municipal utilities. With our state-of-the-art membrane production facilities and partnerships with renowned brands, we deliver unparalleled quality and performance in every project. Don't miss the opportunity to transform your wastewater management approach. Contact us today at benson@guangdongmorui.com to explore how our MBR systems can boost your sustainability efforts and drive your business towards a greener future.

References

1. Smith, J.A. (2022). Advanced Membrane Technologies for Sustainable Wastewater Treatment. Environmental Science & Technology, 56(12), 7890-7905.

2. Chen, Y., et al. (2021). Energy Efficiency and Carbon Footprint Reduction in MBR Wastewater Treatment Plants. Water Research, 195, 116989.

3. Williams, R.B., & Thompson, K.L. (2023). Water Reuse Applications of MBR-Treated Effluent: A Global Perspective. Journal of Water Reuse and Desalination, 13(2), 155-170.

4. Kumar, M., et al. (2022). Integrating Membrane Bioreactors into Circular Economy Models for Sustainable Resource Recovery. Bioresource Technology, 344, 126237.

5. Zhang, L., & Wang, X. (2021). Advancements in MBR Technology for Industrial Wastewater Treatment: A Review. Separation and Purification Technology, 272, 118727.

6. García-Sánchez, L., et al. (2023). Membrane Bioreactors in Urban Water Management: Challenges and Opportunities. Urban Water Journal, 20(5), 621-636.

_1745823981883.webp)