Leachate DTRO Treatment Equipment

Application:Landfill Leachate Treatment

Power consume:65kw/hour

Recovery rate: 50-70%

Inlet COD: <25,000

- Product Description

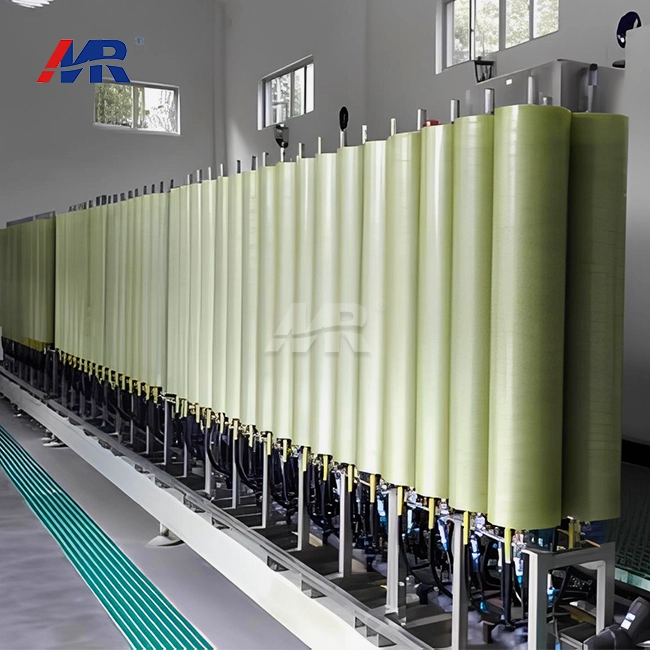

High-Efficiency Leachate DTRO Treatment Equipment Systems for Landfill Compliance & Contamination Control

Landfill operators face intense pressure to meet environmental regulations while managing complex leachate compositions. At Guangdong Morui Environmental Technology, our Leachate DTRO Treatment Equipment delivers precise, scalable solutions to tackle high COD levels (up to 25,000 mg/L), heavy metals, and salinity. With 500+ projects completed globally, we engineer systems that reduce operational costs by 30% and ensure compliance across EU, US, and Asian standards.

Why Choose Our Leachate DTRO Treatment Systems?

✅ 19+ Years of Proven Expertise

Specializing in membrane technology since 2005, we’ve optimized DTRO systems for landfill leachate, PFAS removal, and zero-liquid discharge (ZLD) applications.

✅ Full In-House Production & Customization

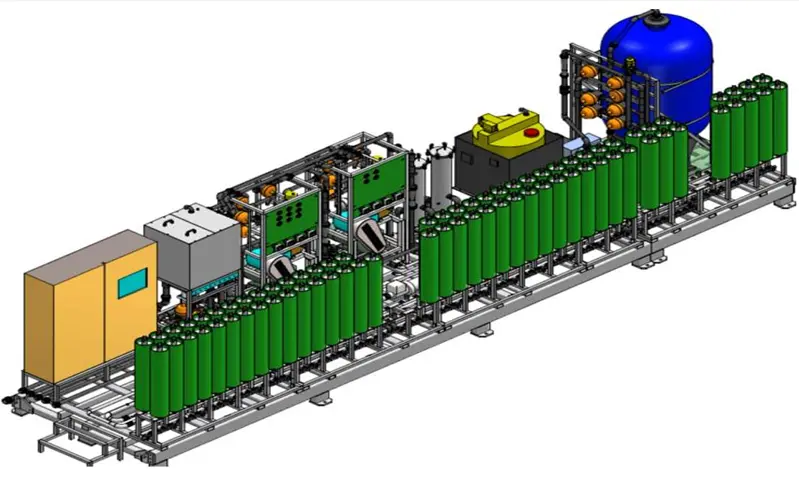

Control every detail—from Danfoss pumps to Toray membranes—in our 15+ workshops. Customize flow rates (5-50 m³/h), materials (316L stainless steel), and automation levels.

✅ Fast Deployment, Scalable Solutions

Pre-assembled skids ship in 20-35 days. Scale from single units (50 m³/day) to multi-skid setups (2,000 m³/day) without compromising efficiency.

✅ 24/7 Technical Support

Get free leachate analysis, onsite commissioning, and predictive maintenance via IoT-enabled monitoring.

✅ Trusted by Industry Leaders

Our ISO 9001, CE, and ROHS-certified systems serve Fortune 500 clients like BYD and CATL.

Product Overview: MR-DTRO-80TD

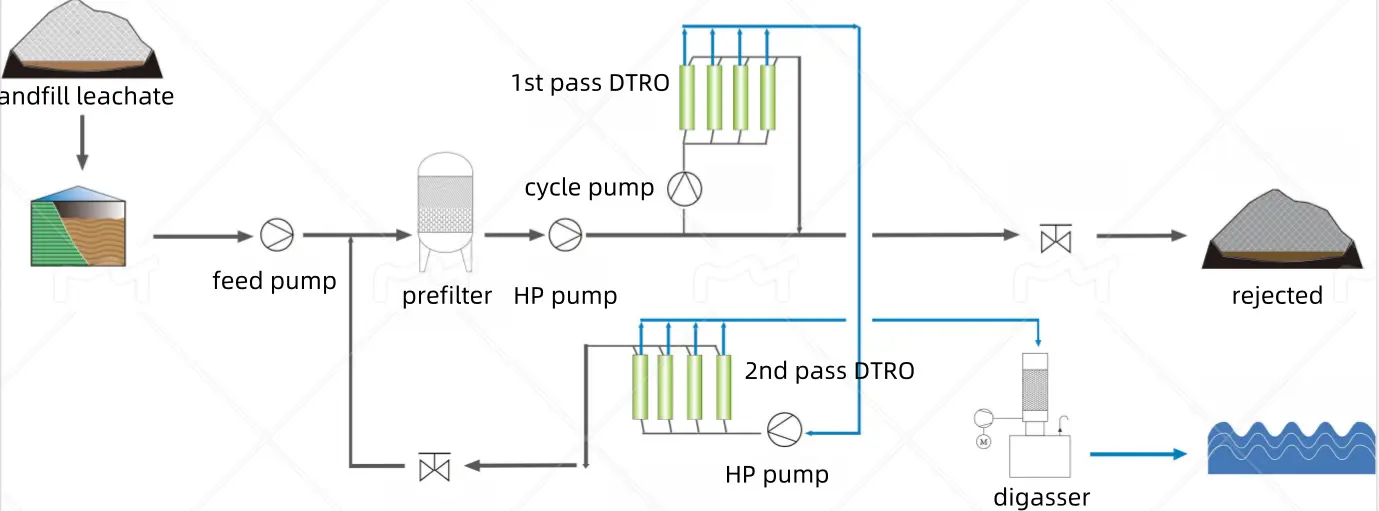

Application: Landfill Leachate Treatment

Power Consumption: 65 kW/hour

Recovery Rate: 50-70%

Inlet COD Tolerance: <25,000 mg/L

Engineered for high-salt environments, the Leachate DTRO Treatment Equipment combines corrosion-resistant materials with anti-fouling membranes to achieve >90% contaminant removal. Its modular design adapts to fluctuating leachate volumes and tight spaces.

Key Benefits for Your Operations

Lower Total Cost of Ownership

- Energy recovery modules cut power use by 25%

- Extended membrane lifespan (3-5 years vs. industry-standard 2 years) reduces replacement costs

Space-Saving Design

Pre-engineered skids require 40% less installation space than conventional systems.

Smart Automation

PLC controls and remote monitoring minimize manual adjustments, ensuring stable pH, pressure, and flow rates.

Technical Highlights

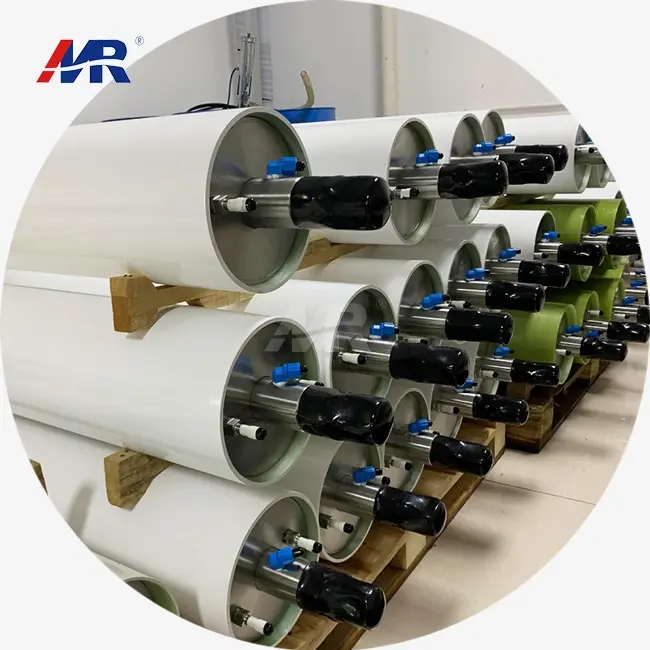

🔹 Advanced DTRO Membranes

98% salt rejection rate with self-cleaning surfaces to resist clogging from oils and organics.

🔹 Durable Construction

High-grade polymers and 316L stainless steel withstand pH extremes and corrosive leachate.

🔹 Water Recovery Optimization

Recover 80%+ of treated water for reuse or safe discharge, reducing sludge disposal needs.

End-to-End Support for Peace of Mind

Pre-Sale Services

- Free leachate sample testing

- Process simulation & ROI analysis

Post-Sale Protection

- 2-year warranty

- Emergency onsite response within 72 hours

- Global spare parts network

Partners & Certifications

Component Brands: Grundfos, Toray, Danfoss, Vontron

Certifications: ISO 9001, CE, ROHS

FAQs

1. How does your equipment ensure regulatory compliance?

Our DTRO systems are pre-configured to meet EU Landfill Directive, EPA Subtitle D, and China's GB standards, with real-time monitoring to maintain discharge limits.

2. Can you handle leachate with fluctuating contaminant levels?

Yes! Automated adjustments to pressure and flow rates compensate for variability in COD, ammonia, or salinity.

3. What makes your membranes last longer?

Proprietary anti-fouling coatings reduce cleaning frequency, extending service life by 30% compared to standard DTRO discs.

4. How quickly can you scale our system?

Add pre-engineered skids in weeks—not months—thanks to modular designs and in-stock components.

Contact Us

Need a Reliable Leachate Solution?

Email benson@guangdongmorui.com for a customized Leachate DTRO Treatment Equipment proposal or technical brochure.

_1745823981883.webp)