DTRO plant

Application:Landfill Leachate Treatment

Inlet COD:<25000

Inlet Conductivity: 8-15ms/cm

Operating Pressure: 120bar

- Product Description

DTRO Plant: Advanced Industrial Wastewater Treatment Solutions

Product Overview

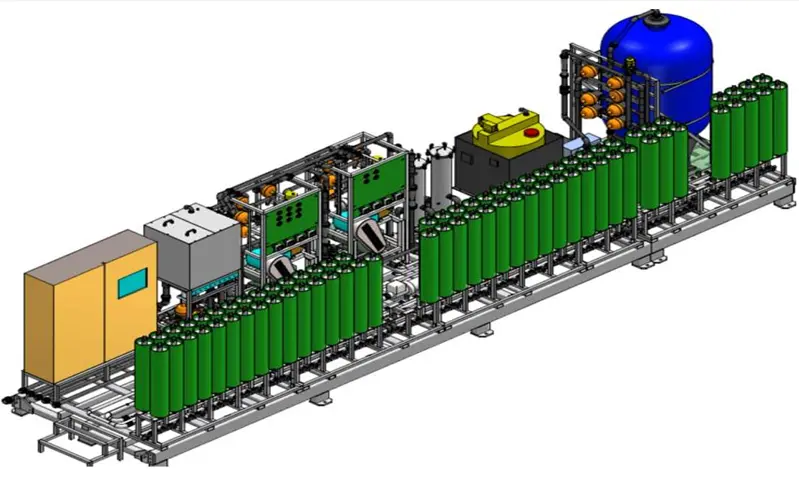

Facing challenges with high-salinity, heavy metal, or chemical-laden wastewater? Our DTRO plant offers a cutting-edge solution designed for industries requiring reliable, compliant, and cost-effective treatment. Specifically engineered for landfill leachate (Model MR-DTRO-120), this system handles inlet COD levels up to 25,000 and conductivity of 8–15 ms/cm at 120 bar operating pressure. Its modular design adapts seamlessly to municipal, mining, and industrial applications, ensuring compliance with global standards like EU directives and China's GB 8978. Whether you're retrofitting aging infrastructure or scaling new projects, our DTRO technology delivers precision where it matters most.

Key Benefits

- High-Efficiency Filtration: Achieve >95% contaminant rejection, even with extreme pH/temperature fluctuations.

- Lower Operational Costs: Energy-optimized systems and durable membranes (2–3+ year lifespan) reduce downtime and expenses.

- Guaranteed Compliance: Meet stringent discharge/reuse regulations effortlessly, backed by ISO/CE certifications.

Product Highlights

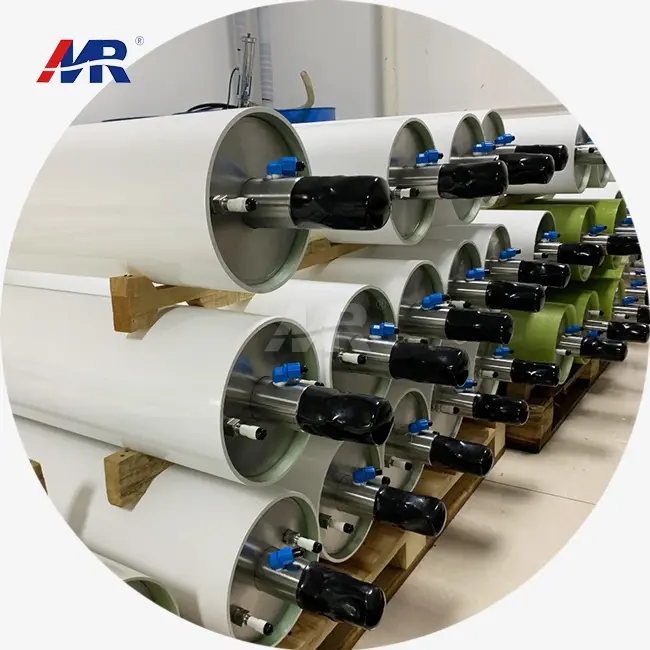

- Built to Last: Stainless steel frames and chemically stable DTRO membranes withstand harsh environments.

- Smart Automation: Real-time PLC monitoring tracks pressure, flux, and TDS for hands-off operation.

- Space-Saving Design: Compact, modular units fit tight spaces without compromising performance.

Why Choose Guangdong Morui?

- End-to-End Expertise: From design to commissioning, we handle it all with 15+ workshops and 10+ factories.

- Premium Components: Danfoss pumps and Toray/Dow membranes ensure unmatched reliability.

- Rapid Support: 14+ branches across China enable 7–35-day delivery and on-site engineer assistance.

Customization Options

- Flexible Configurations: Choose single-stage to multi-stage setups for varying contaminant loads.

- Material Upgrades: Opt for titanium alloys or hybrid systems (e.g., DTRO + evaporation) for acidic/niche effluents.

- Seamless Integration: Pair with UF/MF pretreatment or existing workflows effortlessly.

Global Support & Logistics

- Fast Deployment: Most systems ship within 3 weeks, with door-to-door delivery included.

- Localized Service: Installation, training, and 24/7 remote troubleshooting available worldwide.

- Long-Term Care: Annual maintenance contracts and spare parts inventory keep your DTRO plant running smoothly.

FAQ

1. What wastewater types suit your product?

Ideal for landfill leachate, mining gushing, and high-salinity mechanical streams.

2. How do you ensure compatibility with our site?

Our engineers analyze your foundation to plan plug-and-play or retrofit-ready units.

3. What's the typical ROI period?

Most clients recuperate costs in 18–30 months through diminished vitality utilize and downtime.

Get Started Today

Free Consultation: Contact us for a tailored DTRO solution.

Download Brochure: Explore technical specs and success stories.

Local Support: Interface with engineers in your locale for quick assistance.

Trusted by Fortune 500 pioneers, our DTRO plant combines development with practicality—transforming wastewater challenges into openings. Let's construct your compliant, future-ready framework together!

_1745823981883.webp)