DTRO for Wastewater Treatment

Application:Landfill Leachate Treatment

Power consume:16kw/hour

Recovery rate: 50-70%

Inlet COD: <25,000

- Product Description

DTRO for Wastewater Treatment: High-Efficiency Industrial Solutions

Product Overview

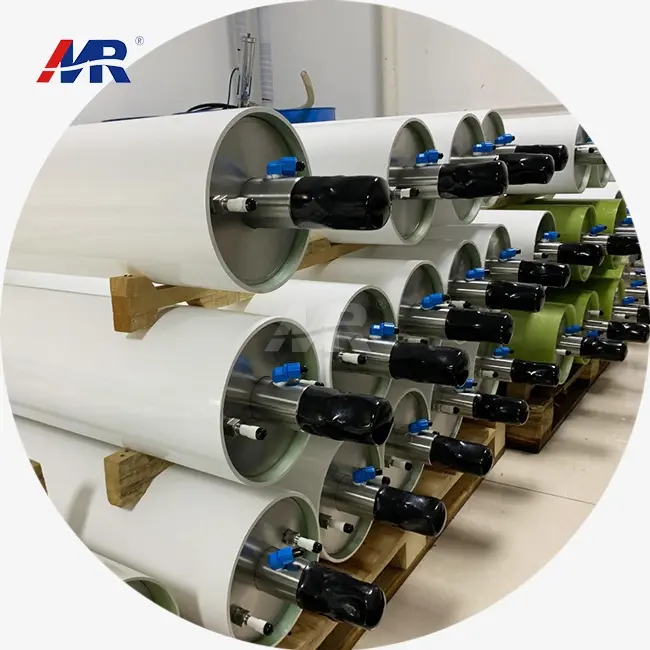

When dealing with complex industrial wastewater, the DTRO for Wastewater Treatment stands out as a robust solution. Designed to handle high-salinity, heavy metal-laden, and organic-contaminated effluents, our MR-DTRO-20TD system ensures compliance with global discharge standards like China’s GB 18918 and the EU’s Urban Wastewater Directive. With a recovery rate of 50–70% and power consumption of 16kW/hour, it’s engineered for municipalities and industries needing reliable, scalable treatment.

Key Benefits

- Superior Contaminant Removal: Achieve >95% rejection of salts, heavy metals (e.g., lithium, nickel), and COD levels up to 25,000 mg/L.

- Long-Term Durability: Anti-clogging membrane coatings resist fouling, even under high-pressure operations (up to 120 bar).

- Cost Savings: Automated cleaning cycles reduce downtime, while energy-efficient designs cut operational costs by 20–30% vs. traditional RO.

- Flexible Scalability: Modular configuration adapts to flow rates from 10 m³/day to 1,000+ m³/day.

Why Choose Guangdong Morui?

With 19+ years of expertise, we’ve delivered 500+ hypersaline wastewater projects for clients like CATL and BYD. Here’s what sets us apart:

- Tailored Solutions: Our engineers optimize systems for your specific wastewater composition, space, and budget.

- Rapid Global Support: 14+ branches ensure 48-hour on-site assistance for emergencies or maintenance.

- Agile Supply Chain: Receive custom-built systems in 7–35 days, backed by ISO/CE-certified quality.

Product Highlights

- Built to Last: Stainless steel and polyethylene modules withstand corrosive environments (pH 2–12).

- Smart Operation: Real-time PLC monitoring tracks pressure, TDS, and pH, alerting you to anomalies.

- Easy Upkeep: Swap membrane discs in minutes—no full disassembly required.

Applications

- Landfill Leachate: Treat high-COD fluids efficiently, meeting strict discharge limits.

- Battery Manufacturing: Remove lithium, cobalt, and nickel from rinsing wastewater.

- Zero Liquid Discharge (ZLD): Integrate with evaporators for full resource recovery in chemical plants.

Certifications & Compliance

Our DTRO for Wastewater Treatment systems meet ISO 9001, CE, and ROHS standards, with pre-engineered setups adaptable to EPA, UL, or WRAS requirements.

Global Support & Service

- Free Pilot Testing: Analyze your wastewater and test our system's performance risk-free.

- 24/7 Expertise: Certified engineers provide remote troubleshooting or on-site commissioning worldwide.

FAQs

Q: How does DTRO handle fluctuating wastewater volumes in manufacturing plants?

A: Modular designs allow easy scaling—add or remove membrane stacks as needed.

Q: What's the membrane lifespan in high-load scenarios?

A: Patented coatings extend lifespan to 5–7 years, with global spare-part hubs for fast replacements.

Q: Can DTRO integrate with existing MBR/ultrafiltration systems?

A: Yes! We design hybrid solutions to maximize efficiency and ROI.

Contact Us

Upgrade your wastewater treatment with a DTRO for Wastewater Treatment system that balances performance and cost. Contact Benson at benson@guangdongmorui.com for a tailored proposal.

_1745823981883.webp)