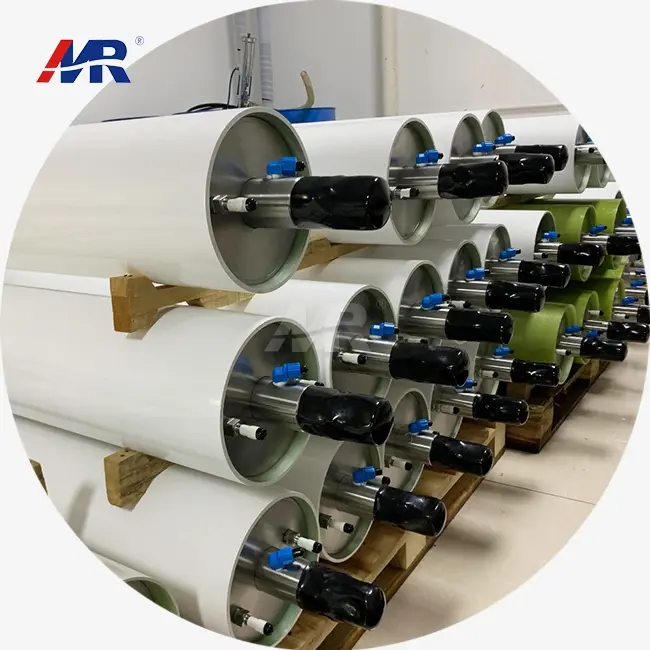

DTRO Elements

Application:Landfill Leachate Treatment

Power consume:32kw/hour

Recovery rate: 50-70%

Inlet COD: <25,000

- Product Description

High-Performance DTRO Elements for Industrial Wastewater Recycling & Zero Liquid Discharge (ZLD)

Industrial manufacturers face mounting pressure to meet strict environmental regulations while managing operational costs. DTRO Elements by Guangdong Morui offer a cutting-edge solution, combining advanced membrane technology with energy-efficient design. Engineered for landfill leachate, battery production, and chemical wastewater treatment, these elements deliver unmatched reliability in high-TDS (up to 120,000 mg/L) and extreme pH conditions.

Why Global Leaders Trust Us

- Certified Quality: ISO 9001, CE, and ROHS compliant.

- Trusted Partners: Collaborations with Toray, DOW, and Grundfos.

- Proven Scale: 15+ factories, 500+ employees, and 35-day delivery assurance.

Key Benefits of Choosing DTRO Elements

Anti-Fouling Design

Minimize downtime with spiral flow channels and 2.5mm optimized membrane spacing, reducing clogging by 40% in oily or emulsified wastewater.

Extreme Environment Adaptability

Operate seamlessly in temperatures up to 45°C, pH ranges of 2-12, and high-saline feeds—ideal for electronics or automotive effluents.

Cost Efficiency

Vertical integration cuts costs by 20% versus competitors, while energy-saving configurations lower power use by 32kW/hour.

Rapid Scalability

Order 50+ units of DTRO Elements with bulk discounts and global technical support for large-scale ZLD projects.

Product Highlights: MR-DTRO-40TD

- Application: Landfill leachate treatment (COD <25,000 mg/L inlet).

- Recovery Rate: 50-70%, adjustable via 5-stage configurations.

- Material: Composite polyamide membrane with PTFE backing for durability.

- Compatibility: Integrates with UF/RO systems and existing ZLD setups.

Why Partner with Guangdong Morui?

End-to-End Engineering

Our in-house team designs pretreatment workflows and post-treatment polishing to maximize your DTRO system’s efficiency.

Direct Factory Pricing

No middlemen mean lifetime savings—every element is produced in our 15+ workshops with strict ISO controls.

Guaranteed Performance

On-site commissioning and 24/7 remote monitoring ensure optimal operation. Backed by a 2-year warranty.

Global Support, Local Expertise

With 14+ branches across Asia, Europe, and North America, we provide:

- Local spare parts inventory.

- Multilingual engineering support.

- Emergency replacements within 72 hours.

Technical Support & Services

- Free Consultation: Custom system design for your wastewater profile.

- Warranty: 2 years on membranes and housing.

- Training: On-site operation and maintenance workshops.

FAQs

Can the product handle heavy metals like nickel?

Yes! Our membranes achieve ≥98% rejection rates for Ni²⁺, even in acidic conditions (pH ≥2).

What certifications ensure compliance?

All elements meet ISO, CE, and ROHS standards, with optional IATF 16949 for automotive clients.

How fast can you deliver 500 units?

35 days—accelerated by our vertically integrated production.

Take Action Today

✅ Request a Free DTRO System Design Proposal (72-Hour Response)

✅ Download Technical Specifications

✅ Schedule a Live Demo (Factory/Online)

Contact Us: benson@guangdongmorui.com

Optimize your wastewater treatment with DTRO Elements—where innovation meets sustainability.

_1745823981883.webp)