Disc Tube Reverse Osmosis

Application:Landfill Leachate Treatment

Power consume:37kw/hour

Recovery rate: 50-70%

Inlet COD: <25,000

- Product Description

Disc Tube Reverse Osmosis Systems for Industrial Wastewater Treatment

Product Overview

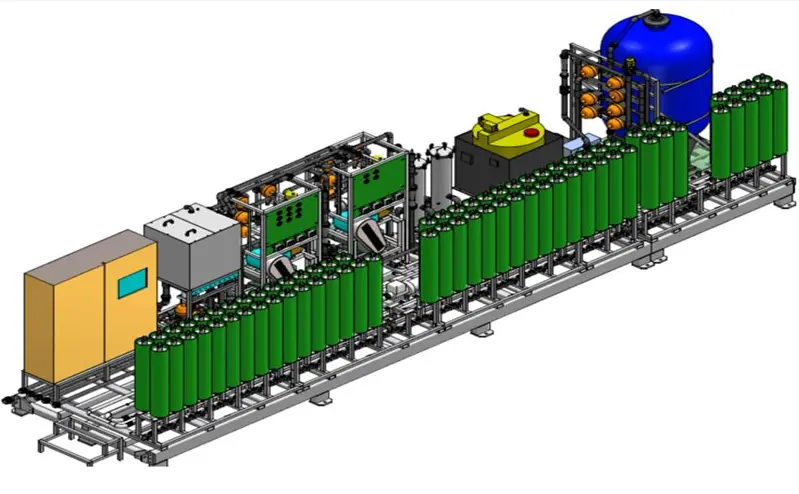

When dealing with high-salinity, high-COD industrial wastewater, Disc Tube Reverse Osmosis (DTRO) stands out as a game-changing solution. Guangdong Morui’s DTRO systems are engineered to tackle complex contaminants like heavy metals, organic chemicals, and oily effluents—common challenges in industries such as battery manufacturing, electronics, and automotive production. With a recovery rate of 50-70% and power consumption as low as 37 kW/hour, our product technology ensures compliance with strict environmental regulations while reducing operational costs. Whether you’re managing landfill leachate or industrial effluents, this system delivers consistent permeate quality (TDS < 500 ppm) even under harsh conditions.

Key Benefits

- 99% Contaminant Removal: Achieve compliance with Zero Liquid Discharge (ZLD) mandates by eliminating heavy metals, salts, and organic pollutants.

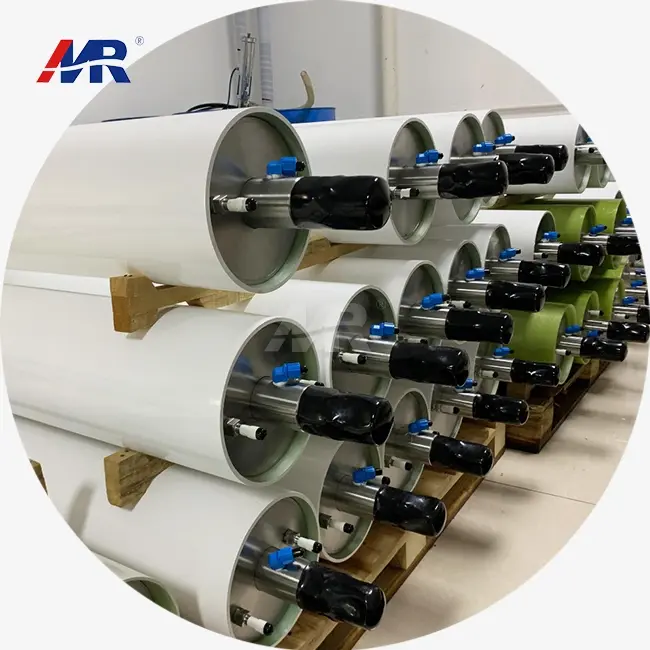

- Durable Performance: Anti-clogging membranes and 316L stainless steel components withstand abrasive/corrosive feedwater.

- Cost Savings: High recovery rates reduce water waste, while energy-efficient designs lower operational expenses.

- Scalable Solutions: Modular configurations adapt to flow rates from 100 m³/day to 5,000 m³/day.

Product Highlights

1. Advanced DTRO Membrane Technology

Our patented disc tube modules minimize fouling risks, even with inlet COD levels up to 25,000 mg/L. This makes them ideal for landfill leachate treatment and battery electrolyte recycling.

2. Smart Monitoring Options

Integrate IoT sensors for real-time tracking of pressure, flow, and TDS. Prevent downtime with predictive maintenance alerts.

3. Rapid Deployment

Pre-assembled skids and containerized units enable installation in tight spaces, perfect for automotive plants or electronics parks.

Why Choose Guangdong Morui?

With 19+ years of expertise in membrane technology, we've optimized every aspect of Disc Tube Reverse Osmosis systems:

- Vertical Integration: Control quality from R&D to assembly across 15+ workshops.

- Global Components: Partner with Toray and Dow to integrate high-performance membranes and pumps.

- Fast Turnarounds: Receive consumables in 7 days or customized systems in 20–35 days.

- Fortune 500 Trusted: Proven success with clients like CATL and BYD in achieving ZLD compliance.

Application Scenarios

- Battery Manufacturing: Treat lithium-ion electrolyte wastewater for safe reuse.

- Electronics: Purify PCB etching effluents containing copper and acids.

- Automotive: Recycle paint shop wastewater to meet sustainability goals.

Technical Support & Services

Our engineers provide:

- Custom Designs: Tailored to your wastewater analysis and reuse targets.

- On-Site Commissioning: Certified teams ensure seamless integration.

- 24/7 Support: Remote troubleshooting and emergency spare parts.

Certifications

All systems comply with ISO 9001, CE, and ROHS standards. Regional certifications (UL, GOST) available upon request.

Global Logistics

With 14+ branches worldwide, we guarantee fast shipping and local technical assistance.

FAQs

1. How does DTRO handle high-salinity wastewater?

The disc tube design prevents membrane fouling, enabling stable operation even with TDS levels exceeding 100,000 ppm.

2. Can you customize systems for battery plants?

Yes. We've designed DTRO solutions for CATL to recover 70%+ of lithium-ion wastewater.

3. What certifications do you hold?

Our DTRO systems meet ISO, CE, and ROHS standards, with optional IATF 16949 for automotive suppliers.

Request Your Custom Solution

Upgrade your wastewater treatment with Guangdong Morui's Disc Tube Reverse Osmosis technology. Contact us at benson@guangdongmorui.com for a free consultation or site assessment. Let's turn your compliance challenges into sustainable success!

_1745823981883.webp)